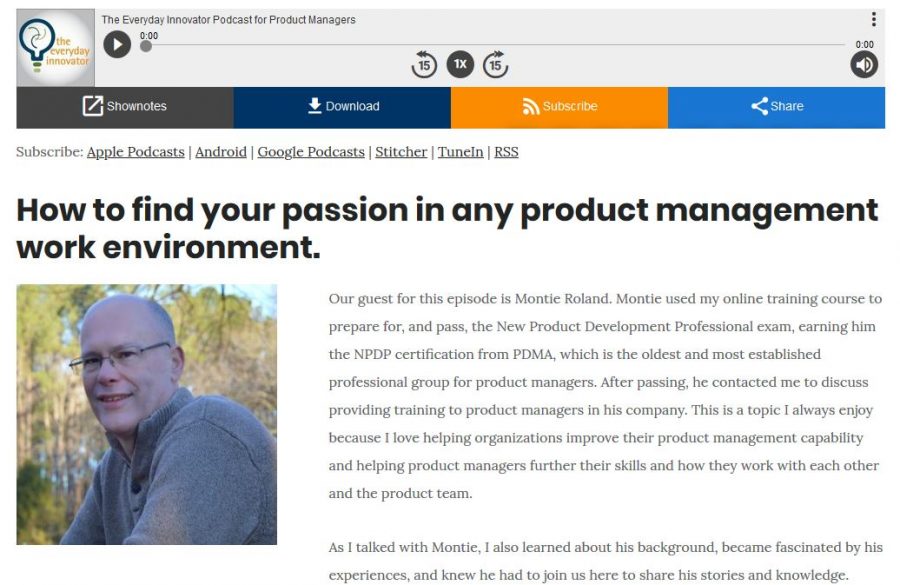

Montie Interviewed on Everyday Innovator Podcast

I was recently interviewed for the Everyday Innovator podcast. This is a great podcast that interviews leaders in the product development and product management field. I’m honored to be included in the podcast.

Excerpts from the interview:

Our guest for this episode is Montie Roland. Montie used my online training course to prepare for, and pass, the New Product Development Professional exam, earning him the NPDP certification from PDMA, which is the oldest and most established professional group for product managers. After passing, he contacted me to discuss providing training to product managers in his company. This is a topic I always enjoy because I love helping organizations improve their product management capability and helping product managers further their skills and how they work with each other and the product team.

As I talked with Montie, I also learned about his background, became fascinated by his experiences, and knew he had to join us here to share his stories and knowledge.

Montie has pursued an entrepreneur path, building his own company, and an intrapreneur path working in an established company. He is a mechanical engineer with a ton of design experience.

We talked about his experiences, including the pros and cons of working for yourself vs working for an organization.

[3:19] What is your current role as an intrapreneur?

I’m on the new product development team at Pentair. If you’ve ever been in a swimming pool, the water probably went through one of our products. I get to do a lot of front-end work in industrial design and the connection between customer and product. The strongest part of my skillset is bridging that gap, and I have the chance to do it on a lot of different projects in a large organization.

[5:26] What kind of products did you create as an entrepreneur?

I ran Montie Design for about a decade. We started in B2B products and eventually moved into B2C. We made rack-mount servers and packaging electronics. Clients would come to us because they were trying to get around politics in their company or were behind schedule on a project. We developed products that they could transition into manufacturing. On the B2C side, we made in-home air filters that were highly stylized. We tried to make as much as we could locally so that there was a community feeling to it. We wanted people to look at our products and say that’s the way they would have made it themselves.

[13:02] What are the advantages of working on your own?

I enjoyed the sense of self-determination. You don’t have someone looking over your shoulder like you do in a big corporation. You can explore directions that you might not be able to otherwise. People who work in product development have an inherent sense of adventure, which tends to be more constrained in a corporate environment.

[14:40] What are the disadvantages of being an entrepreneur?

It requires a lot of work. If you have a spouse or family, you need to have buy-in for your entrepreneurial endeavor at home. You also need to have the funding you need and scale your operation based on the funding you have. I had a great time working on my own, but went back to the corporate world because I needed a lifestyle change. I scaled my business back as a result and now do Montie Gear on the side.

[20:45] What are the advantages of working for an organization?

I’m part of a large, multi-disciplinary team that has a lot of depth. There are times when you might have to switch projects and hand off what you’re working on to another engineer who is a better fit. Pentair fosters the sense of trust necessary to make those transitions happen. It’s also much closer to a 40-hour work week and I don’t have to worry about everything. I have a lot of people around me who are experienced at product development, which pushes me to keep my skills sharp. My colleagues and I challenge each other, which creates a very collaborative environment. I get to focus my time designing things and don’t need to worry about all the other aspects of running a business.

[25:55] What are the disadvantages of working for an organization?

There’s a lot of skepticism from companies about hiring entrepreneurs because they think you’ll get tired of the corporate environment and be out the door to do your own thing in six months. Look for companies that see your entrepreneurial background as a benefit because you can bring different skills to the table. It’s also difficult for HR to translate entrepreneurial skills into existing roles and job levels. You need to be flexible about starting at a lower rung and working your way up over time. Another disadvantage is that you’re not responsible for every decision; the scope is much smaller and you need to be okay letting go of some responsibility. There’s also a culture shift because every company’s culture is different.

[32:58] Why did you pursue the PDMA NPDP certification?

It’s easy to back off on training and certifications when you’re an entrepreneur because you’re so caught up in the day to day of running the business. In a corporate environment, you have time and money for professional development. The company wants you to grow and that makes it really easy do things like certifications.

Innovation Quote

“A candle loses nothing by lighting another candle.” – James Keller

Thanks!

Thank you for being an Everyday Innovator and learning with me from the successes and failures of product innovators, managers, and developers. If you enjoyed the discussion, help out a fellow product manager by sharing it using the social media buttons you see below.

Design Story – Montie Gear in the Field – Hunter’s Friend

Montie’s Note: Here is a Montie Gear product story that gives a insight into the design and a use case that includes testing and field use by the designer. This was a customer newsletter item.

Fall is synonymous with whitetail deer hunting in the South. Our wives become “deer widows” for 2-3 months while we disappear into the woods and look for that giant buck we’ve been watching for. Wives get used to seeing their husbands up late at night looking a pictures from trail cams and learn to cook venison. Saturday mornings are viewed from 20 feet up in a tree stand. Good times and priceless moments.

The Hunter’s Friend was initiated by a suggestion from Al Davis, owner of AllFab Solutions. He is an avid hunter and wanted a way to hang his bow or rifle from a tree without having to run a screw into the tree and damage the tree. A few weeks later, the Hunter’s Friend was born.

Getting your gear to the field and into the tree stand means work. Gear that you take up to the tree must be compact, lightweight and easy to deploy. Setting up your gear while you are hanging from a tree and 20 feet up means it must be well designed and flawlessly task at hand. Anything else is just something that will get left at home.

The Hunter’s Friend holds your bow (or rifle) in the ready position. Holding your bow, or rifle, in your lap can be tiring after a few hours. The Hunter’s Friend solves that problem while keeping your bow at the ready position. I also use it to hold my calls, binoculars and range finder. It straps around the tree without damage so you keep the landowner happy.

I believe that we have 3 in stock so don’t delay in ordering yours, or suggest it as a gift. Check out the pictures below from a recent hunt in Chatham County, NC.

Enjoy those priceless moments!

Click Here or on the image to order

Click Here or on the image to order

Click Here or on the image to order

Click Here or on the image to order

![]()

![]()

![]()

![]()

Write a Review – Get an Awesome Coupon!

Do really like your Montie Gear slingshot, AR-Rest or other product? Help us tell the world about the Handmade, Heirloom Quality products that we make right here in NC!

Reviewing your Montie Gear product is a great way to give potential customers access to your opinion before they buy. We’ve streamlined the review process to make it quick and easy for you. Please a take a few minutes and review your Montie Gear products by going to www.montiegear.com, logging into your account, navigating to your favorite Montie Gear product at www.montiegear.com and then click on “Add Review”. Once your review is submitted, please email me at montie@montie.com and I’ll email a coupon code good for 25% off your next purchase!

Our philosophy for Montie Gear products is pretty straight forward. We provide “Heirloom Quality Products That are Troublesome Gap Tough”.

Many products in today’s world are meant to have a limited life time. A good example is that cell phone that you need to replace every two years. It works great, but over time technology changes and the fragile electronics have a limited lifetime. We want to design and sell products that have a very long lifetime and may actually get passed along to your kids or grandchildren. Many rifles get passed along from parent to children, sometimes marking a rite of passage. Granted a shooting rest isn’t as special as your Grandfather’s rifle. However, we work to design and sell products that are simple, elegant and high enough quality that you will want to pass them along to your kids or grandchildren.Troublesome Gap Tough

Troublesome Gap is a place in Western North Carolina, near the peak of Hap Mountains and overlooking Spring Creek, NC. My parents purchased the property over 40 years ago. I grew up spending time there. We cut firewood for heat, picked blackberries and raspberries, and spent some great weekends up there. Troublesome Gap is remote and rugged, the prefect place to test our products. Troublesome Gap Tough means that the products are rugged and easy-to-use. A delicate, hard-to-use product is a liability in the field, so we avoid that by making sure all our products provide a great customer experience and are built to last, even in demanding conditions.

As President of Montie Design, I am proud the fact that we are shipping high-quality, U.S. made products. I am also proud to be an American.

Sincerely,

Montie Roland

800-722-7987

My Journey Into Lean Manufacturing – Kano Model / Don’t Forget Customer Delight

Greetings,

Can you get so Lean (Lean Manufacturing) that you get lost in the process? You bet you can.

Lets talk about the Kano model. The Kano model helps you to organize your product development and management efforts between basic expectations, performance enhancements and delightful additions to your product. Understanding the difference and applying this model to your product management and design management ultimately serves as a reminder to not forget the joy of creating delightful products that please your customers is great ways. Don’t end up getting lost in the process and forget to delight your customers.

Comments and suggestions are always welcome: montie@montie.com.

Cheers,

Montie

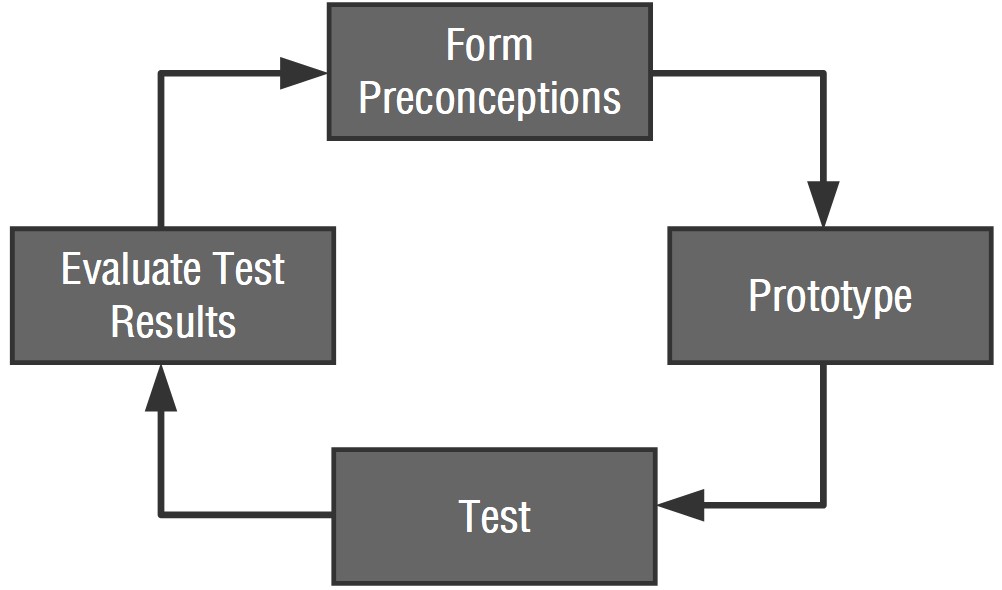

Who You Are and Why Your Designs are Better Because of It

Forget about designing from a clean sheet of paper. It can’t happen. The designer himself prevents brings a tapestry of experience, skills and preconceptions with him. Embrace that diversity and create better designs, even when you are starting from scratch. Once you understand you, then you can think on a broader scale and truly innovate on your next project!

This is a podcast I originally created in 2012.

Cheers,

Montie

montie@montie.com

—————————————————————————–

Audio File Transcript: Who Are You and What Does that Mean

Hello. My name is Montie Roland. And I’m with Montie Design in Morrisville, North Carolina. I wanted to spend a few minutes with you this morning talking about who are you and how does your skillset, your drive, your . . . how you go about creating new product concepts or new product ideas; how does that fit into everything.

We all have our own desires, drives and I want to kind of go through it and talk about it. And maybe learn a little bit about each other as we go through it.

I’m the president of Montie Design and also the president Montie Gear in Morrisville, North Carolina. Montie Design is a product development firm. And we develop products for you. And we fill in gaps. Sometimes it’s a small project; sometimes it’s a large one. And what we do is fill in those gaps in your engineering or your industrial design or your prototyping department; fill in those gaps to help get your product to market.

Montie Gear is a company that provides outdoor shooting equipment, and slingshots and fun stuff. Montie Gear was founded about four years ago as one of those things we decided as an institutional learning tool. And we decided that we wanted to design some of our own products, not just everybody else’s. So we did a couple and then said, well, what would it be like to sell them? How do we sell products without spending a lot of money on advertising? So, we put them on our website, Montie Design website, and then we also came up with the idea – thanks to Carl – of doing a lot of test and evaluation units. And over the years that test and evaluation unit approach has even rolled into a service we now call Social Reviews. And so, I don’t want to spend all day talking about that. Something we’re proud of. Montie Gear line has grown from zero to over a hundred thousand dollars in sales in about four years with very little advertising. So we’re very proud of that and we’re proud of the products we sell.

So it gives us a little different perspective on the product development process. So, not only do we develop products, we also are responsible for some of those products for selling, and manufacturing them. And that’s also kind of spilled over in that we’re now doing that for two clients where we’re providing the backend services – they sell them, and we ship them. We make sure they’re manufactured, that they’re packaged, they’re QC’d and then the customer’s happy.

And so, first question, our first thought is I want to throw out the thought of, you know, who is Montie? Who am I? If I’m going to tell you how other people are, I’m thinking maybe I should go ahead and kind of do a little analysis on myself. Now, Montie Design designs products for a wide variety of situations – manufacturing approaches. We have products that we design – they’re going to go straight overseas. We have products that we design and we get to a certain point and we turn them loose to an ODM somewhere the other end of the Internet and they take it from there; and we read about it in a magazine. We other products we’re more intimately involved with throughout the whole lifecycle. But, you know, it comes down to the “Who’s Montie” and how I think. I think the best example is to maybe watch what I do and not what I say in this case and look at Montie Gear.

With Montie Gear we’ve come at it from the standpoint of we want to have a high quality product that’s what we call heirloom quality-Toublesome Gap tough. Which means a very robust product that’s going to perform well in the field and it’s going to be the kind of product that you want to give to your grandkids because it’s that lasting and hopefully timeless.

So, right there, you kind of have to ask, well, how many of those products are high-volume. And the answer is very few. So we have mainly products that are low-volume, low-capital requirements – and by low-capital requirements, we haven’t built a lot of tooling; we haven’t spent a lot of money to get the products to market. Now the trade-off with that, of course, is the products cost more to manufacture, so you have a higher quality product, higher cost of goods sold, but at the same time that fits in with the Montie Gear approach where what we want to have is this heirloom quality, made local, products.

So, when I go to create a product for Montie Gear, or work with someone on our team that does, or work with an intern or what have you, we’re definitely in the mode of Let’s-get-something-out-there-fairly-fast, without spending a lot of capital investment; without a lot of investment. So, we want to design it, have it work well, but not rely on the fact that we’re going to injection mold it to get the price down or what have you; die cast it, and have to sell gazillions instead. We’re going to plan to sell handfuls at a time. So, in this case, my natural instinct is to rely on local manufacturers for Montie Gear, and to work with those local manufacturers closely to have a higher quality product sold at lower volumes – higher cost, but at the same time the higher quality and also that emotional appeal of having a product that the down the street made (which I think is having more and more value in our society). At the same time, if we’re going to have a higher-end product, we need to provide a higher level of customer service as well. So what we want to do there is to treat that customer well and make sure that we meet their needs on a timely basis.

So if we take that a little farther and look at it in a broad perspective, there’s several different kinds of companies. One company is a company that’s service excellence. They may not be terribly innovative, but you get the same service every time. A great example of this is McDonald’s. You know what you’re going to get no matter where in the United States you go; and to a certain extent, you’ve got a good idea of what you’ll get no matter where in the world you go. So, their goal is to bring you a reliable product at a reliable price, and get it to you quickly and have no surprises. So, it’s a safe bet. You stop and eat at McDonald’s, you know exactly what you’re going to get. That’s not a terribly innovative company at this point. It may have been innovative early on by driving the concept of fast food and so forth. But at this point, it’s a mature company and they don’t do a lot of innovations. They do little tweaks here and there. And they definitely don’t create a lot of new intellectual property; at least, that goes into their products. Most of the intellectual property goes into logistics, service.

So let’s look at other companies that have to innovate. So, kind of break it down into two different types. One is a product excellence company. So a product excellence company is a company where you know that you’re going to get the finest product you can get. You’re going to get a high quality product; you’re going to get service to go with it. So, the whole experience is excellent. They may or may not be innovative, but at the same time, you’re going to get this high quality, high satisfaction product. A good example is that you may go buy a ring for your wife (or your husband); and that ring hasn’t really changed a whole lot. You got a little filigree here and its silver instead of gold, but for the most part, your expectations is very high level of quality. Not a lot of innovation in that industry, I would argue, for the most part. There’s some artistic work but not a lot of what I describe as true innovation. And then another example is a company that’s very innovative, or it could also be very inventive, where they create new intellectual property. And so, in either situation that organization is relying on either innovating or inventing to drive their products ahead of their competitors. And that’s a very important part of the whole ecosystem as well. And that’s the ones a lot of times we tend to really want to get behind. And everybody just wants to always tell the example of Apple, but they’ve come up with some really great products by often by innovating and inventing. And so they’re an example of a company where they try to stay ahead of the curve. And a good example of that is if they don’t, they’re products don’t always compete as well because of cost. So, they want to have this innovative customer experience, these innovative products; but as those products age, there are a lot of times that “me, too” products are a lot more attractive. A good example of that is the iPhone is now starting to be displaced by other smartphones, where at first they were “me, too” – for example, Samsung, HTC – but now they’re starting to actually have some innovation and some invention in what they do. And so they’re competing very well. And if you look at the iPhone 5 versus the latest HTC or the latest Samsung, there’s starting to be a technology gap, which in this case isn’t in Apple’s favor because they really relied on having this amazing edge in the marketplace. Now, they also have a lot of other things going for them, but in the realm of phones, that edge is absolutely critical to maintain their market share.

This also applies to smaller organizations. I like going to the Apex farmers’ market. And there are several folks there that cook different types of items. So, one example is there’s a lady there that makes pies and she makes muffins and so all the recipes she’s using are pretty old school. There’s not a lot of innovation. So, what she’s bringing to her product is quality; its handmade from scratch; these very desirable elements, but there’s not a lot invention or innovation that goes into that. So, if you look at this in the context of the three categories I described earlier, she’s in the service excellence category, or product excellence. So, she’s using her time buying some materials and turning that into a product. Now, in no way am I denigrating that as a model for business. There are a lot of very successful businesses that do that. Think about how many large cookie companies there are. And so, it’s a very valid way of doing business. I think the important thing is that if you’re in that type of business, it’s often handy to understand what your model is to help you make future decisions and current decisions.

So a lot of the folks that we buy stuff from that make pies and pastries at the farmers’ market, there’s just not a lot of innovation there. So, they want to provide a high quality product; they want to provide a friendly face; and it tastes good. You like the fact that the person you’re talking to made it yesterday or this morning, put their time and love into it. And so that’s a good way to look at that. The other categories you find in different places. So, for example, if you’re an inventor, then generally when someone considers themselves to be an inventor, or we consider them to be an inventor as an organization, they have an interest in creating intellectual property, and then selling the concept. So, they’re truly inventing. So, in this case, they’re viability as a service provider (or as a vendor) to someone is their ability to innovate. So, they fall in that last category because if they come up with a concept that’s already out there and it’s a “me, too”, as an inventory they really haven’t invented anything. When you look at entrepreneurs, the entrepreneur – and I want to define the inventor as someone who invents for the sake of invention-to-license later – an entrepreneur is someone who builds a company and an infrastructure that is designed around selling a product; manufacturing and selling it. It’s an important distinction.

So when the entrepreneur does this, the entrepreneur may be making pies to sell at the flea market; may be making cupcakes; and in the last few years there’s been this huge amount of cupcake industry forming. It’s really amazing how many cupcake companies there are. These companies that make cupcakes make some amazing cupcakes sometimes. So you can go and get a cupcake at the grocery for $2.50; or you can go to a specialty store – you might get a $20.00 cupcake. Yes, a $20.00 cupcake. So, could a cupcake company kind of fall into these categories? Well, yes. A cupcake company could be a matter of picking twelve existing cupcake designs, styles, and then making those. And in that case, their appeal is service. They’re providing a product that’s based upon their labor. So it’s not a real inventive product in that case. But there are also cupcake manufacturers and cupcake stylists that provide cupcakes that are very different. And they’ll actually do research into different ways that they can do this. Or maybe come up with their own. So, there may be a new style of icing or a new style of . . . packaging. You know, what can they do different that sets them apart? Now, the question to ask is – Are you selling cupcakes because you have something that’s truly original? It’s a, I don’t know, vacuum-puffed cupcake that no one else can do. And you’ve got this trade secret on how to make vacuum-puffed cupcakes. Or, are you selling products that are just based on your hard work and love? And usually there’s a mixture of the two. But, so, it’s important to understand how your business thrives based on where you are in these models. Because then, all of a sudden, you can make better decisions about how much time and resources and money you should put into these different activities. So if having inventive cupcakes doesn’t drive sales, then maybe you’re putting too much effort into inventing those crazy, new technology cupcakes. If the fact that you sell these crazy vacuum-puffed cupcakes is what is driving your new sales (or your existing sales) in a big way, if that’s what’s driving your growth, then maybe you need to put more effort into the crazy ones.

And so it goes a little beyond just the matter of the accounting; saying this cupcake sold this many, this cupcake sold this many. I think it also goes into the strategic planning. So I think it’s important to plan your strategy around what type of company you are. And so understanding these distinctions and where you fall, and how where you fall helps your business grow, is very, very important. This type of strategic planning and understanding is important at the Fortune 500 level; its important at the small business level. Because it important for anyone in a small business to make sure that you’re always, always – always – making good use of your resources. And understanding, you know, your place in the process of developing new products; or not developing new products helps you make the best decision to maximize your return on investment. Which is critical because it’s a small business; it’s tough enough to survive even if you’re making good decisions. So, making better decisions may be a different between subsistence and true growth and just kick-butt kind of company. And I think how you go about product development, or don’t, is an important part of that and can help you dramatically.

I hope this podcast is helpful. This is a tough subject to sometimes kind of articulate through and work through and walk through with you. So I hope it was helpful. Understanding your spot in your strategic model and what the strategic value of your . . . or what the value proposition of your company is, is something that can really help.

Let me know if you have any questions. Montie Roland, Montie Design. (M-O-N-T-I-E)@montie(M-O-N-T-I-E) .com. Visit us on the website – (M-O-N-T-I-E)@montie(M-O-N-T-I-E) .com. There’s a handy little chat tool and you can click on it and get immediate help. Either way, it’d be great to hear from you. And have a great day. Montie Roland, out.

My Journey into Lean Manufacturing – Part 2 – Active vs. Passive Data

10 years ago, the push was to go paperless. Is paperless too much of a good thing?

Data in your computer is passive. Yes you can manipulate it, share, mine it but you have to go ask for it. Why not make data active?

Lean Manufacturing techniques include tools to make your data active but getting it out in from of your employees and managers on daily basis. Put that data in front of your team an understandable and actionable format where it does the most good, i.e. right in front of them.

Lets explore the various facets of active vs. passive data. Comments and suggestions are welcome here or at montie@montie.com

Cheers,

Montie

Here is the transcription from the podcast………………………………………………..

Audio file: 2015 May 17 – Lean Thoughts 1 – Active vs. Passive Data.mp3

Time transcribed: 12:29 minutes

[Opening music]

Hi. My name is Montie Roland. I’m with Montie Gear in Apex, North Carolina.

What I wanted to do is to share some thoughts with you today and have at least a one-way dialogue – it could become two, if you email me – about the difference between passive and active information. So I’d like to spend a few minutes talking about that. And maybe define it and have some examples.

One of the things that’s happened over the past twenty years is that we’ve had this head-long rush to get everything on the computer. So, we assumed that getting it on the computer is more efficient; is more cost-effective; is safer because you can back it up. And so we’ve created database after database after database. And one of the joys and the beauties of – and potentially harm – of doing this is that everybody can have access to information, without having to go down the hallway and grab something from a file cabinet. Now, of course, the horror is that can be hacked. Someone can get into that from across the world. Whereas, a file cabinet, you’ve got to physically be there to get into it. Now, a file cabinet can be broken into as well, but someone on the other side of the globe isn’t going to be able to do that without visiting here. So, we’ve created this electronic database that contains what we do. And the beauty of it is that everyone in your company can sit down, and if they have the right software and they have the access, they can read that data. The problem is that they have to go read it; they have to go look for it. So I’m going to call that passive data. Now, active data is data that’s right up in your face. And for those of y’all that are family with lean, you’re going to start going “Oh-ho, this is exactly where he is headed” because with lean the goal is to use vertical surfaces as . . . well, I shouldn’t say the goal. Lean is going use boards, charts and effectively, use your vertical surfaces as a way that in an instant you can look at a chart, and have an idea of that particular part of your business and what’s happening in there. And so in lean, there’s a lot of different charts and you chart different areas. And so the idea being that in seconds you can know what’s going on. So, let’s throw out an example. So, one example would be if I have a database of a soccer game. And what I’ve done is, through the magic of the computer and a vision system, I’ve tracked where the ball is, where the people are, what their speeds are, how fast they’re moving, how fast the ball is moving, how . . . blah-blah-blah. So, I have this giant database of excruciating detail regarding the performance of every player on the field. And somewhere in there I have the fact there was a goal scored at this point – point-oh-oh . . . twenty-seven minutes, three seconds and two milliseconds, the ball entered the net. So, if I want to know what’s happening in the soccer game, now I’ve got to have a way to visualize all that data. So, I’ve got to go to the computer; I’ve got to use my visualization tool; I’ve got do all this stuff. But the beauty of it is if I want to know what that player’s performance is, or that team’s performance is, I can do that ad infinitum. Now, let’s make a contrasting example. So, I’ve got the computer database with all this wonderful information. And then the contrasting example is I go to the game. So at the game, there’s several key elements involved – there are players on the field; there’s a ball; from where I’m sitting, I can see the ball. There’s two goals, there’s two goalies (or a football, for our European listeners). And so, I’m in the stadium. I can see the scoreboard. The scoreboard gives me a few pieces of information – what’s the score, what’s the time remaining in the half, what’s the, you know, which half are we in. And so, those pieces of information are there. I can see the ball moving. I can see the ball going in the net. Well, maybe I’m not sure. Did it miss the net? Or did it go in the net? Oh, I look at the scoreboard – boom! So, by going to a soccer game, I can instantly know what’s going on from anywhere in the stadium. So the beauty of it is that I don’t have to have a visualization tool; I don’t have to bring out my computer – it’s all right there, between the scoreboard with an absolute minimum of information (but the right information) – and – watching it unfold on the field, I always know what’s going on just by a glance. Whereas if I monitor this on the computer with this huge amount of data, I have to go to the computer; I’d have to figure out to get what I want and so forth. Now, I think it is important to, you know, throw out there, that you can have a visual board on the computer. I’m going to make the argument that the difference between something you printed this morning and what’s on the computer, effectively if the data is current, it doesn’t matter. And the beauty of printing it on the wall is that someone can walk by and in an instant and see it. And you’ve got a lot more wall space than you have monitor space.

So, yes, there are lean set-ups where people put their display, their information, on monitors. Now, that means you’ve got to bring that information into that display. Maybe it’s automatically from other systems. But the idea is that active information is something that you can glance at and get an answer. You may be glancing at a giant monitor; you may be glancing at a color print-out or a black-and-white print-out that’s hanging on the wall when you walk in the building. But one of the things you see with lean – and lean being, you know, the popular name for the Toyota manufacturing system, is you see active information that’s organized and updated, and that active information lets you know what’s going on. And is a way of communicating what’s going on in an instant because you look at a chart, you know what to look for, you see the colors, you see the ways that everything’s laid out. So now, in an instant, you’ve been updated. Which is a great way to communicate.

So, the opposite of that is passive information, where you’ve got to go to the computer, sit down, look it up on a spreadsheet or look it up here, or do what have you. And so, I’m going to make the argument that where you can use active information, you’re in a much better position because someone doesn’t have to spend the time to go look it up; and also, someone can walk in, know what they have to do, have a constant reminder of where they are and what they’ve got to do; how things are going – because it’s right there and that information’s available. That helps everyone in your organization make better decisions because they’ve got the information they need, and it’s timely and they can make decisions that are timely. And every day every employee makes thousands of decisions. So if you leave them in the dark, they’re guessing at what’s best for the company. If you inform them, give them a structure, educate them, and, you know, lay this all out, now, all of a sudden, those thousands of decisions can be decisions that are the best, the ideal ones, that help get the product out the door quicker with high quality and conserving resources.

So, that’s why I think understanding the difference between active and passive information’s important. And then, also, putting that understanding to use in terms of getting that information to everyone. Now from a Montie Gear perspective. So one of the things that I’ve been thinking about as I’ve been taking my journey into lean is how to implement that in a small company. So, maybe that’s a discussion for another time. But I hope that this has been a good bit of information for you. Give you a little better understanding of that difference between active and passive information, and why it can be so valuable to give your employees the information they need to make those good decisions all day long, every day. Because they’ve got the information they need and then they can act on it.

So, have a great day. Montie Roland, signing off.

[Closing music]

My Journey into Lean Manufacturing – Part 1

Join me as I chronicle my journey into lean manufacturing! This is part 1 of the series. Comments and suggestions are always welcome at montie@montie.com.

Here is the transcript from the podcast……………………………………

Audio file: 2015 May 17 – Lean Thoughts 0.mp3

Time transcribed: 15:50 minutes

[Opening music]

Hello. My name is Montie Roland. And I’m with Montie Gear in Apex, North Carolina. Today, I’d like to spend a few minutes and talk about my journey into Lean, and what I’ve learned in the past few months.

So, let’s back up and let’s talk about, you know, what is lean? Lean is a popular name for the Toyota manufacturing system. Toyota has spent a lot of effort and time and intellectual capital in developing a state-of-the-art way to make cars. The Toyota manufacturing system is the model for the rest of the world. When you hear someone in business talk about that their company is lean, or they’re going lean or what have you, it’s about putting into practice that basically leaner, a version of the Toyota manufacturing system.

Toyota has a really, really, really well-thought-out way of making cars. And this applies to other segments of their business as well, not just manufacturing. It applies to their . . . to their dealerships; it applies to other areas that are ancillary to their manufacturing of their cars. They’ve got to sell them; they’ve got to service them. And so, as I understand it, the principals of lean and the application of lean has been put in place by Toyota throughout their entire system (as far as I know). I know that dealerships put it in place. They definitely put it in place on the manufacturing. And so, it’s important to have an understanding of what “lean” is.

So one of the guidelines behind lean is that you want to optimize your process. Now, a lot of times when you’re talking to someone about lean, first thing they say is, “Well, lean is about reducing waste.” And so, when someone says that and looks at you, you should say, “No! It’s not. It’s a by-product of lean, is reducing waste.” And you get a . . . sometime they’ll maybe tilt their head, look at you, and go, “Well, no. This is . . . in lean, we reduce waste.” So, I want to make the argument that in lean you’ve got two directions that you can do optimization; two main directions – you can always optimize, you know, a lot of different ways. But, there are two main directions that you can optimize for. One is that you can optimize for resources. So that means that you can try to keep everybody busy; you can try to make the best use of space; make the best use of materials; make the best use of personnel; keep your per-unit cost low. And that’s a good thing. However, the challenge with that is that you end up inevitably, by optimizing for resources, you end up developing silos. And by a silo, what I’m talking about is that if you’re, let’s say, the person that assemblies widgets; then, your pay and your bonuses may be directly driven by how many widgets you build. Well, and that’s fine until the point where the person who takes your widgets and ships them can’t keep up. At that point, you may be making widgets, but they don’t have the capacity to ship; or maybe the capacity to sell. So at this point, you’ve got an incentive to continue making widgets because if you’re not making widgets, well, you’re efficiency goes down. And when that efficiency goes down, your incentive goes down. So, now we have a problem because you can imagine that even if it’s not this severe of an example, every group is going to be evaluated based on that group’s performance. Well, when you do that, that’s great; what you’ve got to watch out for, though, is does that group’s performance help the company as a whole. And so they may be amazingly efficient – but – something they’re doing is the part of being so efficient may make someone else inefficient. At that point – mmm, maybe you’re not doing the right thing.

So, this is a natural outcome of building silos and optimizing for resources. So in lean you’ve got to do more than just optimize for resources. What you’ve got to do is you’ve got to optimize for flow. So when you optimize for flow, you have to establish communication between groups. Now, you may have a corporate culture that is absolutely wonderful, where people, you know, talk; they communicate. And everything is wonderful. But a lot of times you have a lot of communication within your group (whatever that group is – manufacturing, shipping) but a lot of times you don’t have communications, let’s say, with accounting. So, if want to optimize for flow, you’ve got to communicate. And that’s the first challenge. And that’s one of the things that lean really tries to address is that communication.

So, let’s talk about optimizing for flow. And what does that mean? Well, when I optimize for flow, I want to optimize for the speed at which I’m adding customer value. What that means is that when I get an order, I want to get that order in this customer’s hands as quickly as possible. Because when I get it in their hands as quickly as possible, then the customer is happier; more delighted or more satisfied. And also, I get paid quicker. So, I don’t have money sitting around in inventory or work-in-progress or what have you. So, lean is all about a customer pull. So, you know, the customer’s making an order – or – we’re filling to maintain an inventory – either one – but we’re going to refill that inventory after its depleted, so you want to refill it as quickly as possible. Or we want to ship as quickly as possible, depending on how the expectations of your customer are and how your industry works.

So what we want to do is we want to get that product made as quick as we can, get it out the door, get it to a customer, and, of course, that being a high-quality product that we made in somewhat an efficient way. So, now you can see what’s at odds is that the most efficient way when it comes to resources may not be the quickest. Now, I want to point out an example. Let’s say that we have four people making slingshots. And let’s say each slingshot takes a month to make (for one person). But let’s say that four people can make a slingshot in five-point-two days. So in this case, if I have four people working on a slingshot at once, there’s some inefficiency because four people have to work together, shared resources, what have you. But, I’ve got the capability to make one slingshot at a time, instead of four at once. And so, the trade-off is that if I look at the folks that make those slingshots and I say “You get paid by how many slingshots you make a month”, then they’re going to say “Well, I’ll make slightly more if we work on them separately”. But then, the trade-off is that it takes a month for one person to make a slingshot. Now, let’s say that I have four people making slingshots and it takes one-point . . . one week and an extra four days, or one month and four extra days to make four slingshots, but I do them sequentially. So, now I’m kicking out a slingshot at just over a week; so a little bit over every week I’m getting a slingshot out the door. Little less efficient – but – now all of a sudden I’m getting it to my customer quicker; I’m getting paid faster. So when you think about, you know, work-in-progress and inventory, that works out well. But it’s not quite as efficient. So if I organize for efficiency, then everybody’s going to want to make one slingshot per person. Or, excuse me, for resource efficiency, everybody’s going to want to make one slingshot per person. If I say I want to get these out as quick as I can, then I’m going to have all four people working on that slingshot, kick that slingshot out; now, I’m shipping a slingshot in a little over a week. So every week, almost, I’m kicking a slingshot out the door. And so this is one of the conflicts that built into lean. So, we want to be efficient and lean has a lot of tools to do that, but lean recognizes right off the bat that you can never be one hundred percent efficient because you also want to optimize for flow. If we’re a hundred percent efficient then the delivery time goes up because of multitasking, because waiting . . . it gets, you know, your deliver time goes up exponentially, not linearly, as you work on multiple things at once. A good example with our slingshots, is that let’s say that it takes a week to ship four slingshots. So now I’ve had four people working on slingshots for a month, and I’ve had . . . or I’ve had one person . . . or excuse, four people working on one slingshot at a time – well, now all of a sudden, if I had limited shipping capacity, then it’s important to not overburden that shipping capacity by forcing them to ship all four slingshots at once. Whereas, if I could spread that out, it may be that I have to have a fourth less people in shipping to ship slingshots, because I’m shipping one at a time, not four at a time.

This is definitely a very arbitrary example, but you kind of get the idea of this . . . dichotomy between optimizing for resources and optimizing for flow. And I think it’s a really important because if you consider lean just purely making your company more efficient then you really aren’t doing lean. You’re not. Lean is about monitoring your process. So, when we go to the next step here is that how do we optimize these things. Well, lean is not as much about the outcome as it is monitoring the process, and improving the process by everybody constantly improving. And so, when you think continuous improvement, you know, well, okay, that means people learn how to make widgets faster. No. Because at some point, a person’s going to sand a corner down only so fast; there’s no . . . that is going to peak, in a way. So instead what we want to do is monitor those processes so we know what’s happening. And so lean is all about monitoring the process, and by monitoring the process and educating the workforce and getting the workforce involved in monitoring, then all of a sudden, as a by-product, everybody’s making better decisions that improve productivity. So, I think that’s a really, really important part of that.

Well let me leave you with this for now. And I know I’ve kind of talked a little bit about lean, but it’s kind of a really neat way to run your business. It’s not a simple thing; it’s an all-encompassing thing. It’s not a couple of charts on the wall. It really is a way to run your business from stem to stern. Lean is not a partial change. It’s a culture change. Without the culture change, then the effectiveness of the lean efforts are dramatically reduced.

Well, Montie Roland, signing out. Have a great day. Bye-bye.

[Closing music]

END AUDIO

Podcast: Giving The Go Ahead To A New Product

Giving The Go Ahead To A New Product

———– Transcript —————————

Audio File: 2014 Feb 12 – Giving The Go Ahead To A New Product.mp3

Audio Length: 10:10 minutes

Hello, my name is Montie Roland with Montie Design in Morrisville, North Carolina. We’re a product development firm with core competencies in mechanical engineering and industrial design.

One of the interesting things that happens working with clients from bigger companies or medium-sized companies – or even smaller ones that are, you know, are growing – is that we’ll design a . . . whatever. And so we’ve designed this project, we’ve gotten to know our contact at that client, and one day after a design review that client looks across the table and says, “You know . . . I’ve got some stuff I’ve been working on in my basement”. It’s interesting that it’s very likely for a client that’s in charge of – or enabling; in charge of, also – product development for his company often will have something that they do on the side. And it’s interesting; so they may enjoy their job and they work very hard at it; at the same time, when they talk about the thing they’re making in their garage, there’s usually this big smile. And so, then what happens is they look at us and say, “That’s why I respect what you did so much with Montie Gear; because I know how tough it is”. And Montie Gear’s our product line that we created four years ago of our own products. We manufacture them; we sell them; we distribute them; we maintain the website . . . well, Daniel helps us. But, so it’s our own products, though. And it’s become kind of this company fascination. But, we’ll have clients that have this emotional connection to our Montie Gear products. Maybe it has nothing to do with the products; it’s just the fact that they really like coming up with new stuff. And so they see us doing it and having a good time and it’s a common situation that we’re both having a good time doing new products.

And so, there’s a couple of thoughts I want to throw at you. And we’ll talk about it from the perspective of an entrepreneur, but this also can apply from the perspective of a big company. Because, if you look at a big company as an organism, some of the same thought processes, many of the same thought processes, apply. They’re modified in some ways but, at the basic level they’re pretty similar.

So, one of the first thought processes is to go after the whole enchilada. It’s go big or go home. Well, the good side about that is that if you go big and you win big, then you profit big. And so, that’s a good thing. So if you go for a product where you’ve stretched what you can do or what your company can do, and it’s a product that can change the market or can take over a market or can grab market share, then Woo Hoo! That can be a big winner because the upside to that is that you can have some big profits. The downside is that you’ve invested a lot in it and you’ve also not invested in other products. Now, form an entrepreneur standpoint, we’ve had one single owner, single employee companies where the owner of the company said, “I’m going to do this. I’m going to go big. I’m going to injection mold this. I’m going to sell these all over the country” and, you know, “Either help me or get out of my way”. And so, the one I’m thinking about at this moment had the funds to back it up. He had the money in the bank to do what he needed to do, and so, he wrote checks. We helped him out. He did other stuff and now he’s got a product that’s starting to take off like crazy. So the upside is going to be huge for him, I think. Good product. Great salesman. Good attitude. Thinking about the business. And thinking about, you know, how he’s going to make all this happen on a big scale and, hey, let’s . . . we helped him push.

And so, we have other clients – and like I said, this can apply to an entrepreneur or to a company – where they’re not in a position yet, for whatever reason, to go for the big score. And so for them the medium-sized score or the smaller score is a much better option. Maybe because of cash flow; maybe because of other resources. Maybe because of time resources. Maybe they’re very business doing something else. So if they go after this major product, then it may take years to get there because they got so much on their plate. Well, the other possibility is to go after a bunch of smaller products, or smaller, I should say, lower effort products. And, then that gets them into that new market. That gets them experience in that market. And one nice thing about that is if you’re tightly resource-constrained, then that experience can help you make wise use of that money by having a less feature-rich product; a simpler product. Maybe instead of having this medium-scope project, you say, “I’m going to do something that we can do in the next eight weeks.” Get that out there; start selling it; see what happens; get some experience. And that’s a call you’ve got to make. You know, we have clients that are going to go for the big score; and that’s what they need to be doing. They’ve got their resources; they’ve got the people; they’ve got the time; they’ve got the talent; and they’ve got the motivation. And we just help them do that. And we have other clients that are much, much better off coming at it from much more of a cottage industry approach. And so, in this case, they’re going to put less capital out and they’re going to sell less. And you know the upside – and maybe two orders of magnitude smaller – but at the same time, they’re not risking other things to do it.

And so that’s kind of where you have to decide is that, you know, what are you going to do? You just got to man up and go. And, I think the trick there is there’s some things to consider. And this is kind of the podcast from a little while back. Where, you know, do you have the funds to do it? Do you have the time? Do you have the energy? Do you have the motivation? Do you have the people? And do you have the people that are in the right spot? And so, there again, this is why all products live or die by the management team. Because that’s where you can make good decisions or bad decisions that, you know . . . if you’re not careful, you’ll make a decision that means you have a product that requires so much effort, it takes you so long to get there, that then there’s a risk you’ll never get there. I would say that with product development, generally, the longer it spreads out, the less likely it is you’ll ever get there. Now, there are exceptions to that, but for the most part that’s true.

So, I hope that you can take something away from this. And, look at it from the standpoint of right-sizing that product for your capabilities, your resources. And there’s nothing to say that if you do a simple product, you can’t come back with a complex product. So, just kind of decide. Think it through.

We’re happy to help you all the way through. Big. Small. Little. Massive. Disruptive. Incremental. We’re the engine that helps you push. And we get in, we help you push and we help you take it from that concept to the shipping dock. And we fill in the holes that you need along the way to get you there. Sometimes they’re small gaps; sometimes they’re big gaps. But, our job is to get in there and push.

I hope this helps out. If you have any questions, please don’t hesitate to give me a call, shoot me an email, visit our website. It’s 1-800-722-7987 – or – 919-481-1845. montie (M-O-N-T-I-E)@montie(M-O-N-T-I-E) .com is my email. Or just visit our website – www. montie.com. Thanks. Hope you have a great day. Bye-bye.

END AUDIO

Podcast: Design Process Steps Funnel

[Transcript]

Audio File: 2014 Feb 25 – Design Process Steps Funnel.mp3

Audio Length: 12:01 minutes

Good Morning. My name is Montie Roland with Montie Design in Morrisville, North Carolina. I’m also with Montie Gear in Morrisville, North Carolina, as well.

Montie Design is a full-service product development firm. We provide everything from taking your concept all the way to a fully designed, fully engineered, ready-to-manufacture product, and helping you get that on the shipping dock. We can provide a value from the engineering side, from the industrial design side, to the project management aspect, and also from product validation, all the way to introducing you to contract manufacturers, and as-needed service liaison between your organization and the contract manufacture to make sure that it’s a win-win for everybody.

The design process has several steps. Those steps are intended to create a funnel. That funnel helps you to minimize the cost of the design process by starting out with a lot of ideas and a lot of concepts and boiling them down to the concept that is going to be the winner in the marketplace.

So, the next question becomes, well, how do you do that? So, if you use the funnel metaphor, with the funnel you’ve got a wide top. Let’s say you’re putting oil in your car. So you’ve got oil coming out of a jug, which is similar to the thought of ideas coming out of your staff, your constituents, your customers, and your stakeholders. And so, you pour that oil into that funnel, and the idea behind the funnel is you’ve got a big target. So all the oil you pour in starts running down the funnel. Well, the same thing; what we want to do is capture those great ideas, capture those concepts – written, verbal, unstated – capture those rules, because you know the design of your product has a lot of rules. And that’s because you’re in a market space where you have experience. So, as you put that experience to use, those rules have value because you don’t want to repeat any missteps in the past and you want to build on successes in the past.

So, what we do is the first step is to do research. There again, the research is akin to putting a second jug of oil in there. So we want to do research, understand what the market’s about. And then also make sure that we’re completely oriented to your market, and hopefully do a lot of the nuances of your market – some of that we have to rely on you; others, we can look at trends and research. So, that design research is the first step. And then the second step is to start pulling out concepts, thoughts, what we call “space shuttle ideas”, and do some ideation. And the initial ideation gets kind of everybody thinking, but I don’t want to pin any super solid concepts down yet; just get everybody thinking. And then what we want to do is do some brainstorming. So, now we’ve done some research, made a few sketches, enough to throw some stuff up on the wall and chew on it. And then we use brainstorming. And brainstorming is where there’s no such thing as a bad idea. Most people use a brainstorming session as a planning session; and it’s not. It’s a good way to ruin your brainstorming. Because some of the crazy ideas don’t work exactly as stated, but may lead to some really solid innovations. So, we brainstorm. Take that brainstorming results and then start doing ideation. Now, one of the steps that I just blew right by here as I was talking is we also want to create a style board. And we do want to do that in the beginning. That’s so that we can understand what you’re thinking. And a style board is to get your thoughts. With a style board, you bring us images, pictures, magazine clippings, polaroids; what have you. And show us things that you like. And, also, concepts that may be difficult for everybody to convey that doesn’t do this for a living, or just may be difficult to convey or it’s just a lot quicker with a photograph. For example, you may see a device on a piece of machinery. Take a picture, bring it to us, and say, I like how this device works; this could work great in our application. Or, I like the color; I like the shape; it could be the rear end of the Audi TT. Wow, these proportions are nice. So, we take that style board and we use that in our ideation. And we’ll also probably create one of our own. So, the brainstorming and the style board are very valuable tools.

Now, for some products, we need to do a personalities and personas session, where, kind of like a style board, we want to dig out a vision. So, with personalities and personas, we’ll design a product for an individual customer, and then we’ll go on to do this for a suite of customers that are very different – demographically, what they’re looking for, what they earn, who they are. You know, in some cases with some products we’ll throw in race and religion because there may be a cultural influence that we want to capture in our product development. And, yes, it’s important that you don’t design products for vanilla people, because vanilla people just don’t exist. So, what we have to do is look at the culture where our product’s going to be sold. If it’s a worldwide product, then we have to look at multiple cultures. What we don’t want to do is to create a product that won’t sell well in a given country because we’ve violated some cultural norm, and that’s really important.

So, then, we’re making sketches. We take those sketches and we review them. And it’s important to spend a lot of time looking and thinking about those initial sketches, because this is the inexpensive part of the project, relatively. Sketches are quick. So then we take those; we narrow a whole wall full of sketches down to a few concepts; work on those concepts. And the whole time we’ve been creating this design buffet. So what we want to do is create all of these concepts and all of these pieces, and then we can pick and choose from those pieces and some of those may integrate well together in the final product. So, there again, we’re starting out with a lot of ideas and then we’re narrowing it down as we go. So now we’ve got sketches of a bunch of ideas; we’ve narrowed that down to, say, one, two or three; and then we take those and refine those. And then we do a review again. Then narrow that down. So, the whole time, everybody’s getting a chance to provide input. If possible, we want to create a massing model. A massing model is a simple prototype that just reflects size and shape – simple, inexpensive, quick, you know, blue foam type prototype. Not something you show to the CEO unless he’s really hands-on. But something you can pass around between the product manager and the engineers and just in a, kind of, a closed circle of review.

And then we take that and narrow it down to one concept. Take that one concept and refine that concept. Get it signed-off. So, everybody needs to sign off, all the stakeholders, that this is the concept we want to move forward with. We take that concept and we go to the engineering stage. In the engineering stage we work out the nuts, the bolts, where everything goes. It’s important during the engineering stage to maintain the vision so that the engineers don’t lose track of what’s the aesthetic vision, what are the values, the, you know, it’s not just a collection of specs and bolts and nuts; it’s a product for a living, breathing people.

Somewhere in that stage we want to build a prototype. We want to build prototypes as soon as possible and as often as possible. So, once we have an industrial design concept and we’re starting to commit this to a solid model, a lot of times its good to build a cruder prototype, but one that’s actual size that may have some of the functionality as we’re going through the engineering process. At the end of the engineering process we want to build a functional prototype; maybe even an alpha unit. We’ve made drawings; we’ve gone out for quotes, created a bill of materials. As early in the process we want to start our bill of materials so that we’re starting to get an idea of what this is going to cost in production. From there, we transition to manufacturing. Make those introductions – Who’s going to make your product? Are you going to assemble it yourself? Is it going to come in a box, ready to go, from a contract manufacturer? We got to think about packaging. We may need to design you some packaging. Got to think about – Is it shipped over the Internet? Or is this a point-of-sale type product, where we need to have point-of-sale packaging?

And so we work through these issues and these challenges and opportunities, and create for you this product. And those are, in a nutshell, the basic steps. If you’re a Fortune 100 company, or an entrepreneur that’s selling your second product, you’re going to follow the same steps – maybe not as formally, but in general – you’re going to follow those same steps. As you can imagine, a change on a sketch early on is inexpensive; a change after you’ve fully engineered the product gets more expensive; and a change after you’ve started producing it is painful. So, what we want to do is pull out that vision; we want to get the stakeholders to weigh in, make sure that important parts of the product and those aspects are fully realized; and we don’t trip over something. Like, for example, an unknown requirement. So, by going through these steps, we minimize the risk of that unknown requirement popping up. And that’s one of the reasons you want to prototype early because usually when you lay something on the table, some of those unstated, understated or just not known products requirements start coming out.

So I hope this has been helpful. If you have any questions, don’t hesitate to give me a call – 1-800-722-7987. It’s Montie Roland. Or, montie (M-O-N-T-I-E)@montie(M-O-N-T-I-E).com. Or www.montie (M-O-N-T-I-E) .com is our website.

I hope you have a great day. I hope this is beneficial. Montie Roland, signing off.

END AUDIO

Podcast: About Montie Design

Montie Design was founded in 2006 by Montie Roland (pdf resume, word, html), a practicing engineer looking for an outlet for his desire to design and engineer great products. Montie Design moved to Morrisville, NC in 2007 to add additional space and locate closer to customers in the Research Triangle area.

As Montie Design has grown, we have been fortunate to work on a variety of awesome projects in diverse markets from electronics to sporting goods. One quarter we’re designing rackmount equipment to go in data center. Another project, we find ourselves designing an environmental test chamber for Aberdeen Proving Grounds to test equipment before it goes out to the warfighter. We’ve created consumer products like the Invisi-ball and the Fog Thief. This type of variety is great because no two projects are ever the same.

Look to us for help with:

- Mechanical Engineering / Product Engineering / Product Development

- Industrial Design

- Prototypes

- Electrical Engineering / Firmware / PCB Layout

- Consultation on Product Viability

- Project Management

- Product / Brand Management

Our President has this crazy passion for designing equipment to make life in the outdoors more fun and more comfortable. This passion was put in motion in 2009 when we started the Montie Gear product line. This was originally started as our own skunkworks for fun. In 3-1/2 years it went from a few concepts to a six figure a year operation. Today Montie Gear is a separate company and has over 30 unique products. While we are very passionate about designing products for camping, shooting and the great outdoors, we stand ready to put that same enthusiasm and knowledge to work designing and engineering great products for you. If you are looking for a shooting rest or slingshot, please www.montiegear.com.

There are several areas where we really stand out with the services that we provide.

Designing and Engineer Low-to-Medium Volume Products

Montie Design excels in the difficult area of designing low and medium volume products. We are experts at balancing capital / tooling expenses with product costs. With decades of experience in product engineering, we are ready to deploy our process and move your product from concept to market.

Electronics Enclosures and CFD / Thermal Analysis

The design phase is critical to keep electronics cool, avoid EMI / EMC issues, and predict thermal issues. We perform thermal analysis in-house using state of the art CFD (computation fluid dynamics) tools for accurate and reliable results.

Outdoor Equipment

We enjoy building rugged equipment for outdoor sporting and downrange applications with experience in shooting sports such as firearm accessories and slingshots. Camping, hiking, shooting and backpacking are passions of ours. We pour that passion into your product! This includes designing accessories for firearms, military, tactical and slingshots.

Gathering Social Reviews for Clients

We connect your new product to active bloggers, writers, and lead users to allow those experts to lend their credibility to your product. This is vital, because most customers now check internet reviews before purchasing. We can assist you in creating this base of reviews that are so critical for customers.

Strong Vendor Network

Take the risk out of receiving your prototype on time! Our great vendors, that we have successfully worked with for years, allow us to extend great service. Our responsive vendors provide a range of services that include waterjet cutting, rapid machining, rapid sheetmetal, paint, powder coat, rapid prototyping, rapid tooling and CNC machining. If we can’t do in-house, we generally have a local vendor that can respond quickly and help us make your prototype, or limited production run, a reality.

Sustainability Analysis Tools

Our easy-to-understand report shows your customers exactly where you stand when it comes to sustainability. There are no difficult to understand metrics. Our common sense approach will update your customers on the success of your product sustainability.

Read more at https://montie.com/#U6K8ukfuzCG59KDV.99

[Transcript]

Audio File: 2014 Feb 17 – About Montie Design.mp3

Audio Length: 11:08 minutes

Hello, my name is Montie Roland. I’m the president of Montie Design in Morrisville, North Carolina. I wanted to take a few minutes to introduce you to Montie Design.

Montie Design is what we call a full-service design firm. We provide mechanical engineering, industrial design, and we also build prototypes. There are also requirements that we need to fulfill for electrical engineering and software development and firmware development. And so we can help with that as well.

Our core competency is those first three – mechanical engineering, industrial design and prototyping. What we do is fill in gaps. We take your project and we go from an estimate to a completed job. Usually a kind of a workflow, when it comes to a project, goes through several stages. The first stage is the information gathering and understanding. Well, what we want to do is understand what you need us to accomplish so that we can put together a proposal. And that proposal is usually an estimate with stages to it. Sometimes we work against an estimate on a time-of-materials basis, and other times we work as a firm fixed price.

Projects go from, you know, creating that estimate to . . . the next stage is usually the industrial design stage. The industrial design stage is where we sit down, work with you to understand your vision. And then take that vision and commit it to concepts on paper. Sometimes those are hand drawn sketches; sometimes those are computer generated assets. But what we want to do is take your vision and pluck that vision out and then get it down on paper so we understand it. Then we also want to take our understanding of other industries and see where we can bring other techniques, other technologies and other approaches to bear. So what we’re trying to do there is to make sure that your product has the benefit of the knowledge that we’ve gained over the years doing projects for other people.

And that way you’ve got a broad perspective on your next product. We want to look and see what, you know, what are people doing in your industry and what are people doing across other industries. Bring that into the product development process so that your product is robust, fits the market, and also, you know, we’ve looked to see where we can bring value to your product and to your customer by bringing in other technologies and other approaches and other thoughts.

So, we take that; generate sketches and additional assets, depending on the project. And then we may build what’s called a “massing model”. And a massing model’s a prototype where it’s really only meant to show size and shape and just general, is it the right size. So, you can hold it. It’s usually not functional, but it gives you a feeling; you can actually put it in your hands, turn it, show it to people. A lot of times what that also does between that and the sketches and the renderings, compare that to your spec or, if need be, we can develop that spec for you. And once you put something down on the table, that’s also when the unwritten requirements come out. Because that’s when someone says, “Hey, Montie. We need to do this” or “No, this can’t be more than two inches tall” or twelve inches or one-six pounds or it needs to do that. And those undocumented requirements are understated requirements then have this opportunity to flow out; we can capture those early on because finding out that the product didn’t perform as advertised at the end of the project is not good. So, we want to capture that in the beginning so we build in success from the front.

We go from there to an engineering phase. As soon as we can we want to build a prototype. In the engineering phase we take our mechanical engineers, start making solid works, solid models. Testing those models with computer-aided tools like finite element analysis or computational fluid dynamics (or CFD) for airflow and thermal analysis. We use that to, I guess, prototype digitally and then pretty quickly we want to build a mock-up. And depending on the project and the scope, some mock-ups may be to test a particular thing; for example, airflow. We might build a mock-up that’s aimed completely at testing airflow to verify and validate our CFD results.

So, then we go through there and build models in the computer (SolidWorks). And then build a prototype. And as we go forward our prototypes, you know, the cost of these prototypes increases. Obviously, if you’ve got a block of foam that someone worked on for an hour its much less expensive than if you have, you know, a fully functional, fully developed engineering-grade prototype that tests out functionality, aesthetics, manufacturing concepts. So we want to match the prototype to your needs, or the needs at that point. There again, so we want to make sure that we’re containing costs where we need to. And make sure that we’re providing you with high value for the money you’re spending.

So, build a prototype. Test that prototype. Make any adjustments to the design based on that testing. And then go out for quotes. So we go out for quotes and come back with a costed bill of material. So you now know what it’s going to cost to build your product and production.

So, we’ve added some tremendous value in several areas here. One is that we’re helping you to leverage our relationship with vendors and component manufactures, contract manufacturers. So we’re taking our relationships, introducing you to the people you need to be introduced to. And then also working with them to generate this costed bill of materials that tells you what it’s really going to cost to manufacture your product at the quantities you want to sell it at. And that’s something we’re good at. That’s something we bring a tremendous amount of value to the table with. Because of those relationships, because of our understanding of how to make this happen, and also, too, to help save you money because you’ve got folks that are on your side (us) and helping you work through questions with vendors and contractors. And so we’re putting our experience to use. And also, you may have all this experience in-house. At the same time, it may be what we’re simply doing is providing a relief for your staff, so they can be doing other potentially higher-value activities, or things that they’re better at, and then we can work on the things we’re good at and get those through your pipeline quicker, and to where they’re on the shipping dock and you’re selling them and you’re adding to your bottom line.

So, at the end of the day, our job is to help you drive towards improving your bottom line. We want to have products that are robust and that are profitable and that are manufacturable. That’s Montie Design. We take you through that process. Our job is to serve you and help you turn that next product concept into that next product winner.

If you have any questions, please don’t hesitate to give me a call – it’s Montie Roland, 1-800-722-7987. Visit us on the web – www. montie.com. Or shoot me an email – montie (M-O-N-T-I-E)@montie(M-O-N-T-I-E) .com. And my staff, as I say, we’re here to serve you; do a good job for you, and add a tremendous amount of value to your product development and engineering process. Please give me a call and let’s talk about that project that’s on your desk, or the one that’s going to be on your desk soon, and let’s make your life a little easier and your company more profitable. Montie Roland, signing off.

END AUDIO

Podcast: Developing A Product

Developing a successful new product requires funding and resources. Lets spend a few minutes talking about how all those fit together with the product development process.

Developing A Product

Transcript

Audio File: 2014 Feb 12 – Developing A Product.mp3

Audio Length: 8:07 minutes

Hello. My name is Montie Roland. I’m with Montie Design in Morrisville, North Carolina.

Whenever you undertake the development of a new product, there’s a series of decisions that go into that product at a very early stage. One of the things that’s very, very important to do is to validate that you should build the product. Because if you build a product that won’t sell, then you’ve tied up resources in something that will never generate a return on investment. So one of the things that I think is very, very important is to develop a skill set of saying, Okay, here’s why I think this product will sell; being able to work through a process of helping you get to that validation. And then being able to take the results of that validation and make a go or no-go decision. This really applies to all practitioners, be it corporate in a monster company, a medium-sized company, or an entrepreneur or inventor.