Powering a Propane Shower Using Your Car Battery

Thanks for following our outdoor adventures!

We just got back from a great week long trip to the Western North Carolina mountains. We camped up at 4000 feet of elevation near Hot Springs, NC. Because we were going to be gone for a week, we took our big tent. That was a lot more comfortable for an extended period, especially with the dog. She takes up a lot of space in the teardrop.

Since we wouldn’t have the teardrop, we had to use an alternate way to power the 12 Vdc pump for the shower. So we used the battery on the 4Runner, which works great. The 4Runner battery has plenty of capacity to run the 10 amp shower pump for the short amount of time needed to take a shower.

Taking a shower in the evenings is a great way to feel refreshed before going to bed. Its really not an option when backpacking, but a nice perk when car camping / glamping or overlanding.

I’ll also show you a simple DIY sink and countertop setup and storage box that works great if you have the room to haul it around or have a place where you can leave it permanently. We leave it at our permanent camping location and use it again and again. You could use this type of sink setup for a glamping trip as well, but you would have to haul it to your camp site. It might work well for a large gathering where you need a good way to wash dishes for a larger group.

Using a water jug like this makes it super easy for everyone to wash hands. That is very handy!

Our storage box setup is great for extra supplies and for storing higher value items when you leave the campsite.

Reminder, always be aware of wildlife around you. I was standing near some tall grass and this guy slithered right by me and set up to sun himself on that log.

We found out that we had a leak in our tent roof, after many years of reliable service. Or quick fix was to use tarps to cover the top of the tent and make it through the week without any more leaks.

As usual, my wife cooked some great meals! Makes the whole trip better.

Choosing Your First Firearm

Shower Setup and the Teardrop – Pimping the Teardrop – Part 2

Should You Wear a Mask – The Science Behind Why You Should

There is so much misunderstanding and misinformation about this subject. So I break down my understanding of why you should wear a mask. It is longer than I intended, but hopefully it is simply stated and makes a good argument for why masks should be worn.

If you physically cant wear a mask (small percentage of the population), that is ok, we just need to get everyone else wearing a mask so we can beat this virus and go one with our lives, liberty and prosperity.

You can listen to the podcast or on Youtube (below).

Connie’s Thoughts on Life During the Corona Virus – Part 2

My Wife’s Thoughts on Life During the Corona Virus

Corona Virus – Minimizing the Impact to Your Business and Family

Here are my thoughts on

- how NC and Wake county are misleading us and not being consistent with CDC guidelines

- why the Corona virus is a threat to your employees, you and your bottom line

- why you should send your employees home sooner, rather than later, to protect your business and bottom line – especially employees that can work from home

- reducing the chance of infection by reducing the potential R0 in your business

- remember as the commentator on PeakProsperity.com says the pattern of the virus is case, case, cluster, cluster, boom

Our local disinformation from the state / county / public schools is so bad that PeakProsperity.com was pointing out the inaccuracy of info provided by Wake County public schools and the Wake county health department in conjunction with NC DHHS.

I’m not a medical professional, but I’ve been following the virus very closely. I hope this helps you make proactive decisions that could save lives.

Montie Interviewed on Everyday Innovator Podcast

I was recently interviewed for the Everyday Innovator podcast. This is a great podcast that interviews leaders in the product development and product management field. I’m honored to be included in the podcast.

Excerpts from the interview:

Our guest for this episode is Montie Roland. Montie used my online training course to prepare for, and pass, the New Product Development Professional exam, earning him the NPDP certification from PDMA, which is the oldest and most established professional group for product managers. After passing, he contacted me to discuss providing training to product managers in his company. This is a topic I always enjoy because I love helping organizations improve their product management capability and helping product managers further their skills and how they work with each other and the product team.

As I talked with Montie, I also learned about his background, became fascinated by his experiences, and knew he had to join us here to share his stories and knowledge.

Montie has pursued an entrepreneur path, building his own company, and an intrapreneur path working in an established company. He is a mechanical engineer with a ton of design experience.

We talked about his experiences, including the pros and cons of working for yourself vs working for an organization.

[3:19] What is your current role as an intrapreneur?

I’m on the new product development team at Pentair. If you’ve ever been in a swimming pool, the water probably went through one of our products. I get to do a lot of front-end work in industrial design and the connection between customer and product. The strongest part of my skillset is bridging that gap, and I have the chance to do it on a lot of different projects in a large organization.

[5:26] What kind of products did you create as an entrepreneur?

I ran Montie Design for about a decade. We started in B2B products and eventually moved into B2C. We made rack-mount servers and packaging electronics. Clients would come to us because they were trying to get around politics in their company or were behind schedule on a project. We developed products that they could transition into manufacturing. On the B2C side, we made in-home air filters that were highly stylized. We tried to make as much as we could locally so that there was a community feeling to it. We wanted people to look at our products and say that’s the way they would have made it themselves.

[13:02] What are the advantages of working on your own?

I enjoyed the sense of self-determination. You don’t have someone looking over your shoulder like you do in a big corporation. You can explore directions that you might not be able to otherwise. People who work in product development have an inherent sense of adventure, which tends to be more constrained in a corporate environment.

[14:40] What are the disadvantages of being an entrepreneur?

It requires a lot of work. If you have a spouse or family, you need to have buy-in for your entrepreneurial endeavor at home. You also need to have the funding you need and scale your operation based on the funding you have. I had a great time working on my own, but went back to the corporate world because I needed a lifestyle change. I scaled my business back as a result and now do Montie Gear on the side.

[20:45] What are the advantages of working for an organization?

I’m part of a large, multi-disciplinary team that has a lot of depth. There are times when you might have to switch projects and hand off what you’re working on to another engineer who is a better fit. Pentair fosters the sense of trust necessary to make those transitions happen. It’s also much closer to a 40-hour work week and I don’t have to worry about everything. I have a lot of people around me who are experienced at product development, which pushes me to keep my skills sharp. My colleagues and I challenge each other, which creates a very collaborative environment. I get to focus my time designing things and don’t need to worry about all the other aspects of running a business.

[25:55] What are the disadvantages of working for an organization?

There’s a lot of skepticism from companies about hiring entrepreneurs because they think you’ll get tired of the corporate environment and be out the door to do your own thing in six months. Look for companies that see your entrepreneurial background as a benefit because you can bring different skills to the table. It’s also difficult for HR to translate entrepreneurial skills into existing roles and job levels. You need to be flexible about starting at a lower rung and working your way up over time. Another disadvantage is that you’re not responsible for every decision; the scope is much smaller and you need to be okay letting go of some responsibility. There’s also a culture shift because every company’s culture is different.

[32:58] Why did you pursue the PDMA NPDP certification?

It’s easy to back off on training and certifications when you’re an entrepreneur because you’re so caught up in the day to day of running the business. In a corporate environment, you have time and money for professional development. The company wants you to grow and that makes it really easy do things like certifications.

Innovation Quote

“A candle loses nothing by lighting another candle.” – James Keller

Thanks!

Thank you for being an Everyday Innovator and learning with me from the successes and failures of product innovators, managers, and developers. If you enjoyed the discussion, help out a fellow product manager by sharing it using the social media buttons you see below.

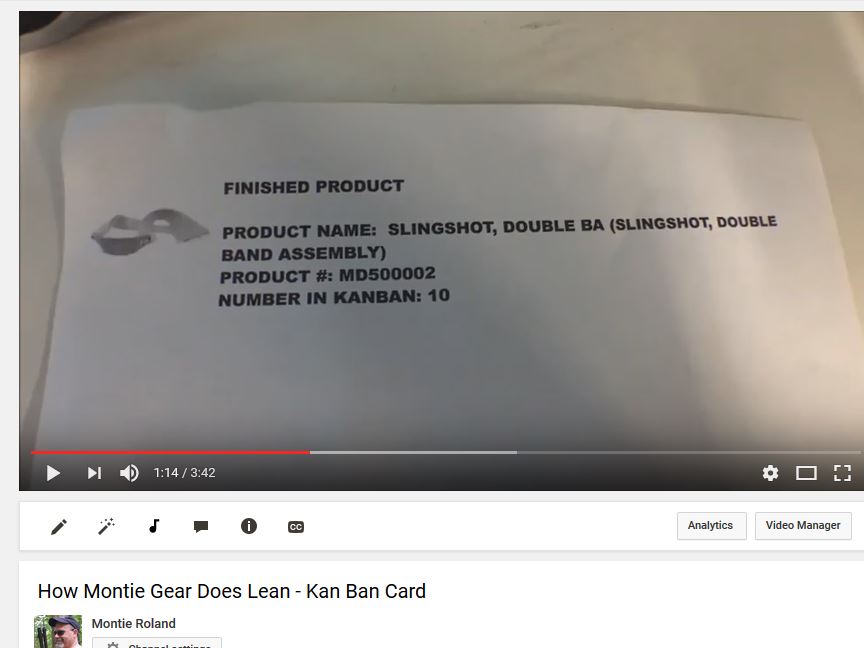

Kanban Cards at Montie Gear

We use Kanban cards at Montie Gear to manage our inventory. The purpose of the cards is to make sure we don’t run out of inventory so we have the products you want, when you want them. Kanban is a way to use a simple formula to determine how much product to keep on hand by using customer demand and the time it takes to produce the product. You can hear more about Kanban cards at:

Lean Shipping Desk – How Montie Gear Does Lean Manufacturing

If you are going lean, the boss has to set the example. One of the places where I spend a lot of time is at the shipping desk. So my 2 second lean project for the week is cleaning up the shipping desk. Here are the results.

Questions, comments, videos, suggestions are all welcome!

Montie

montie@montie.com

Montie Gear is Transforming into a Lean Manufacturer

My Journey Into Lean Manufacturing – Kano Model / Don’t Forget Customer Delight

Greetings,

Can you get so Lean (Lean Manufacturing) that you get lost in the process? You bet you can.

Lets talk about the Kano model. The Kano model helps you to organize your product development and management efforts between basic expectations, performance enhancements and delightful additions to your product. Understanding the difference and applying this model to your product management and design management ultimately serves as a reminder to not forget the joy of creating delightful products that please your customers is great ways. Don’t end up getting lost in the process and forget to delight your customers.

Comments and suggestions are always welcome: montie@montie.com.

Cheers,

Montie

Who You Are and Why Your Designs are Better Because of It

Forget about designing from a clean sheet of paper. It can’t happen. The designer himself prevents brings a tapestry of experience, skills and preconceptions with him. Embrace that diversity and create better designs, even when you are starting from scratch. Once you understand you, then you can think on a broader scale and truly innovate on your next project!

This is a podcast I originally created in 2012.

Cheers,

Montie

montie@montie.com

—————————————————————————–

Audio File Transcript: Who Are You and What Does that Mean

Hello. My name is Montie Roland. And I’m with Montie Design in Morrisville, North Carolina. I wanted to spend a few minutes with you this morning talking about who are you and how does your skillset, your drive, your . . . how you go about creating new product concepts or new product ideas; how does that fit into everything.

We all have our own desires, drives and I want to kind of go through it and talk about it. And maybe learn a little bit about each other as we go through it.

I’m the president of Montie Design and also the president Montie Gear in Morrisville, North Carolina. Montie Design is a product development firm. And we develop products for you. And we fill in gaps. Sometimes it’s a small project; sometimes it’s a large one. And what we do is fill in those gaps in your engineering or your industrial design or your prototyping department; fill in those gaps to help get your product to market.

Montie Gear is a company that provides outdoor shooting equipment, and slingshots and fun stuff. Montie Gear was founded about four years ago as one of those things we decided as an institutional learning tool. And we decided that we wanted to design some of our own products, not just everybody else’s. So we did a couple and then said, well, what would it be like to sell them? How do we sell products without spending a lot of money on advertising? So, we put them on our website, Montie Design website, and then we also came up with the idea – thanks to Carl – of doing a lot of test and evaluation units. And over the years that test and evaluation unit approach has even rolled into a service we now call Social Reviews. And so, I don’t want to spend all day talking about that. Something we’re proud of. Montie Gear line has grown from zero to over a hundred thousand dollars in sales in about four years with very little advertising. So we’re very proud of that and we’re proud of the products we sell.

So it gives us a little different perspective on the product development process. So, not only do we develop products, we also are responsible for some of those products for selling, and manufacturing them. And that’s also kind of spilled over in that we’re now doing that for two clients where we’re providing the backend services – they sell them, and we ship them. We make sure they’re manufactured, that they’re packaged, they’re QC’d and then the customer’s happy.

And so, first question, our first thought is I want to throw out the thought of, you know, who is Montie? Who am I? If I’m going to tell you how other people are, I’m thinking maybe I should go ahead and kind of do a little analysis on myself. Now, Montie Design designs products for a wide variety of situations – manufacturing approaches. We have products that we design – they’re going to go straight overseas. We have products that we design and we get to a certain point and we turn them loose to an ODM somewhere the other end of the Internet and they take it from there; and we read about it in a magazine. We other products we’re more intimately involved with throughout the whole lifecycle. But, you know, it comes down to the “Who’s Montie” and how I think. I think the best example is to maybe watch what I do and not what I say in this case and look at Montie Gear.

With Montie Gear we’ve come at it from the standpoint of we want to have a high quality product that’s what we call heirloom quality-Toublesome Gap tough. Which means a very robust product that’s going to perform well in the field and it’s going to be the kind of product that you want to give to your grandkids because it’s that lasting and hopefully timeless.

So, right there, you kind of have to ask, well, how many of those products are high-volume. And the answer is very few. So we have mainly products that are low-volume, low-capital requirements – and by low-capital requirements, we haven’t built a lot of tooling; we haven’t spent a lot of money to get the products to market. Now the trade-off with that, of course, is the products cost more to manufacture, so you have a higher quality product, higher cost of goods sold, but at the same time that fits in with the Montie Gear approach where what we want to have is this heirloom quality, made local, products.

So, when I go to create a product for Montie Gear, or work with someone on our team that does, or work with an intern or what have you, we’re definitely in the mode of Let’s-get-something-out-there-fairly-fast, without spending a lot of capital investment; without a lot of investment. So, we want to design it, have it work well, but not rely on the fact that we’re going to injection mold it to get the price down or what have you; die cast it, and have to sell gazillions instead. We’re going to plan to sell handfuls at a time. So, in this case, my natural instinct is to rely on local manufacturers for Montie Gear, and to work with those local manufacturers closely to have a higher quality product sold at lower volumes – higher cost, but at the same time the higher quality and also that emotional appeal of having a product that the down the street made (which I think is having more and more value in our society). At the same time, if we’re going to have a higher-end product, we need to provide a higher level of customer service as well. So what we want to do there is to treat that customer well and make sure that we meet their needs on a timely basis.

So if we take that a little farther and look at it in a broad perspective, there’s several different kinds of companies. One company is a company that’s service excellence. They may not be terribly innovative, but you get the same service every time. A great example of this is McDonald’s. You know what you’re going to get no matter where in the United States you go; and to a certain extent, you’ve got a good idea of what you’ll get no matter where in the world you go. So, their goal is to bring you a reliable product at a reliable price, and get it to you quickly and have no surprises. So, it’s a safe bet. You stop and eat at McDonald’s, you know exactly what you’re going to get. That’s not a terribly innovative company at this point. It may have been innovative early on by driving the concept of fast food and so forth. But at this point, it’s a mature company and they don’t do a lot of innovations. They do little tweaks here and there. And they definitely don’t create a lot of new intellectual property; at least, that goes into their products. Most of the intellectual property goes into logistics, service.

So let’s look at other companies that have to innovate. So, kind of break it down into two different types. One is a product excellence company. So a product excellence company is a company where you know that you’re going to get the finest product you can get. You’re going to get a high quality product; you’re going to get service to go with it. So, the whole experience is excellent. They may or may not be innovative, but at the same time, you’re going to get this high quality, high satisfaction product. A good example is that you may go buy a ring for your wife (or your husband); and that ring hasn’t really changed a whole lot. You got a little filigree here and its silver instead of gold, but for the most part, your expectations is very high level of quality. Not a lot of innovation in that industry, I would argue, for the most part. There’s some artistic work but not a lot of what I describe as true innovation. And then another example is a company that’s very innovative, or it could also be very inventive, where they create new intellectual property. And so, in either situation that organization is relying on either innovating or inventing to drive their products ahead of their competitors. And that’s a very important part of the whole ecosystem as well. And that’s the ones a lot of times we tend to really want to get behind. And everybody just wants to always tell the example of Apple, but they’ve come up with some really great products by often by innovating and inventing. And so they’re an example of a company where they try to stay ahead of the curve. And a good example of that is if they don’t, they’re products don’t always compete as well because of cost. So, they want to have this innovative customer experience, these innovative products; but as those products age, there are a lot of times that “me, too” products are a lot more attractive. A good example of that is the iPhone is now starting to be displaced by other smartphones, where at first they were “me, too” – for example, Samsung, HTC – but now they’re starting to actually have some innovation and some invention in what they do. And so they’re competing very well. And if you look at the iPhone 5 versus the latest HTC or the latest Samsung, there’s starting to be a technology gap, which in this case isn’t in Apple’s favor because they really relied on having this amazing edge in the marketplace. Now, they also have a lot of other things going for them, but in the realm of phones, that edge is absolutely critical to maintain their market share.

This also applies to smaller organizations. I like going to the Apex farmers’ market. And there are several folks there that cook different types of items. So, one example is there’s a lady there that makes pies and she makes muffins and so all the recipes she’s using are pretty old school. There’s not a lot of innovation. So, what she’s bringing to her product is quality; its handmade from scratch; these very desirable elements, but there’s not a lot invention or innovation that goes into that. So, if you look at this in the context of the three categories I described earlier, she’s in the service excellence category, or product excellence. So, she’s using her time buying some materials and turning that into a product. Now, in no way am I denigrating that as a model for business. There are a lot of very successful businesses that do that. Think about how many large cookie companies there are. And so, it’s a very valid way of doing business. I think the important thing is that if you’re in that type of business, it’s often handy to understand what your model is to help you make future decisions and current decisions.

So a lot of the folks that we buy stuff from that make pies and pastries at the farmers’ market, there’s just not a lot of innovation there. So, they want to provide a high quality product; they want to provide a friendly face; and it tastes good. You like the fact that the person you’re talking to made it yesterday or this morning, put their time and love into it. And so that’s a good way to look at that. The other categories you find in different places. So, for example, if you’re an inventor, then generally when someone considers themselves to be an inventor, or we consider them to be an inventor as an organization, they have an interest in creating intellectual property, and then selling the concept. So, they’re truly inventing. So, in this case, they’re viability as a service provider (or as a vendor) to someone is their ability to innovate. So, they fall in that last category because if they come up with a concept that’s already out there and it’s a “me, too”, as an inventory they really haven’t invented anything. When you look at entrepreneurs, the entrepreneur – and I want to define the inventor as someone who invents for the sake of invention-to-license later – an entrepreneur is someone who builds a company and an infrastructure that is designed around selling a product; manufacturing and selling it. It’s an important distinction.

So when the entrepreneur does this, the entrepreneur may be making pies to sell at the flea market; may be making cupcakes; and in the last few years there’s been this huge amount of cupcake industry forming. It’s really amazing how many cupcake companies there are. These companies that make cupcakes make some amazing cupcakes sometimes. So you can go and get a cupcake at the grocery for $2.50; or you can go to a specialty store – you might get a $20.00 cupcake. Yes, a $20.00 cupcake. So, could a cupcake company kind of fall into these categories? Well, yes. A cupcake company could be a matter of picking twelve existing cupcake designs, styles, and then making those. And in that case, their appeal is service. They’re providing a product that’s based upon their labor. So it’s not a real inventive product in that case. But there are also cupcake manufacturers and cupcake stylists that provide cupcakes that are very different. And they’ll actually do research into different ways that they can do this. Or maybe come up with their own. So, there may be a new style of icing or a new style of . . . packaging. You know, what can they do different that sets them apart? Now, the question to ask is – Are you selling cupcakes because you have something that’s truly original? It’s a, I don’t know, vacuum-puffed cupcake that no one else can do. And you’ve got this trade secret on how to make vacuum-puffed cupcakes. Or, are you selling products that are just based on your hard work and love? And usually there’s a mixture of the two. But, so, it’s important to understand how your business thrives based on where you are in these models. Because then, all of a sudden, you can make better decisions about how much time and resources and money you should put into these different activities. So if having inventive cupcakes doesn’t drive sales, then maybe you’re putting too much effort into inventing those crazy, new technology cupcakes. If the fact that you sell these crazy vacuum-puffed cupcakes is what is driving your new sales (or your existing sales) in a big way, if that’s what’s driving your growth, then maybe you need to put more effort into the crazy ones.

And so it goes a little beyond just the matter of the accounting; saying this cupcake sold this many, this cupcake sold this many. I think it also goes into the strategic planning. So I think it’s important to plan your strategy around what type of company you are. And so understanding these distinctions and where you fall, and how where you fall helps your business grow, is very, very important. This type of strategic planning and understanding is important at the Fortune 500 level; its important at the small business level. Because it important for anyone in a small business to make sure that you’re always, always – always – making good use of your resources. And understanding, you know, your place in the process of developing new products; or not developing new products helps you make the best decision to maximize your return on investment. Which is critical because it’s a small business; it’s tough enough to survive even if you’re making good decisions. So, making better decisions may be a different between subsistence and true growth and just kick-butt kind of company. And I think how you go about product development, or don’t, is an important part of that and can help you dramatically.

I hope this podcast is helpful. This is a tough subject to sometimes kind of articulate through and work through and walk through with you. So I hope it was helpful. Understanding your spot in your strategic model and what the strategic value of your . . . or what the value proposition of your company is, is something that can really help.

Let me know if you have any questions. Montie Roland, Montie Design. (M-O-N-T-I-E)@montie(M-O-N-T-I-E) .com. Visit us on the website – (M-O-N-T-I-E)@montie(M-O-N-T-I-E) .com. There’s a handy little chat tool and you can click on it and get immediate help. Either way, it’d be great to hear from you. And have a great day. Montie Roland, out.

My Journey to Lean – Part 3 – Can Montie Gear go Lean?

Join me and talk about the first steps in considering how Montie Gear could go Lean.

Normally, when you think about Lean Manufacturing it is in the context of a large manufacturer. Can a micro manufacturer go Lean? Six Sigma? Lets talk about it.

Comments welcome at montie@montie.com

Cheers,

Montie

Here is the transcription from the podcast……………………………………………..

Audio file: 2015 May 17 – Lean Thoughts 2 – Lean at Montie Gear – Can it be done.mp3

Time transcribed: 17:58 minutes

[Opening music]

Hi. My name is Montie Roland. I’m with Montie Gear in Apex, North Carolina.

I want to spend a few minutes having a chat and a little bit of dialogue, and talk about the first steps towards implementing lean at Montie Gear.

So, I’ve been on this journey of learning lean. And, what does it mean? You know, what does it really mean? Not just, you know, overarching concept, but how do you make it work? You know, and how does combine work? How does, you know, work site visits work? How do MDI boards work? So, there’s all these things, these tools that lean uses to monitor your process and communicate to everyone.

So, now the trick is how to implement that in a very, very, small, micro-manufacturing environment. I’m going to make the argument that a lot of the tools in lean are going to apply even to a micro-manufacturer. And, at first, you sit there and say, “Well, yeah, if I want to tell John something, I’m going to lean across the table and tell him. I mean, there’s only three of us” – blah-blah-blah. Okay, so, I still think that there’s a place for lean within the organization because it helps you monitor your process. And in a small company, monitoring the process often doesn’t happen, because you assume it’s not worth it; you don’t have the manpower; you’re too busy putting out today’s fire; or just barely getting stuff out the door; keeping things resourced efficient. But, I think there’s more to it than that. So, one of the things that we want to do with lean is we want to optimize for flow first, and optimize for resource efficiency second. So, optimizing for flow means we want to get stuff out the door; optimizing as quickly as possible to the customer. So we want to add that value as quickly as possible. Whereas optimizing for resources means we want to do it as cost-effectively as possible. Well, the problem with putting too much of an emphasis on optimizing for resources is that it’s easy to create silos where people are thinking, Wow, I’m doing a great job. I’m cost efficient. But, then, what they’re doing isn’t necessarily getting the product out the door to the customer as quickly as possible, which interferes with cash flow. Because the quicker it gets to the customer, the quicker the cash flow happens, and the happier the customer, or more satisfied.

So, one of the things that we were already doing (and I didn’t realize how it already really fit into lean until after we started learning all this) is that . . . two things. One is that we were already doing single piece flow. So, in lean, lean’s going to most likely push you to single piece flow. So, single piece flow means that you build your products in a continuous manner down the line. So, in the past, you might have had facilities where someone with, let’s say, building a rifle – they’d make two-hundred-and-fifty barrels. And then everybody would go and they’d make two-hundred-and-fifty triggers. Then they’d go and make two-hundred-and-fifty stocks. So, what happens is that you’re putting all this in inventory while you’re finishing. This is kind of an extreme example. But with single piece flow, once we start the process of making a product, then it goes all the way through the process as quickly as possible. So, instead of having ten people making one part, we’re going to have ten people doing ten steps to make that part. So, now the advantage is that we have less inventory, and once we start making a product it goes through the line fairly quickly. So, if we were making all the pieces in a batch mode, then it takes a while when there’s a customer order for you to fill that order. Now, so, really quickly, there’s two ways that pull works. One is that you build to a certain level of inventory based upon your expected sales over a given period, and you maintain that inventory. So when that inventory is depleted, then there is a call to make more inventory, there’s an authorization to make more inventory, and that authorization results in the manufacturing floor making those parts to bring that level back up to that inventory level. The other way to do that would be you made-to-order, so you got an order for fifty, so now you make fifty. So, what we want to do is get that order through and out the door as quick as we can.

So, when we think about a slingshot and put it in that prism, a slingshot is a combination of batch and single piece flow manufacturing. For example, we’re not at a quantity level, where we make enough parts so that we paint every day. So as a result, we will make, for example, a bunch of slingshot frames, and then those will get cut at a vendor’s location. And they want to cut a minimum. You know, there’s work in setting it up, running it. And so they want to sell us a minimum of slingshots in a batch, otherwise it’s not cost effective to make them. So, there’s a batch of slingshots that’s cut on the waterjet, and then they go to paint as a batch. Now, and currently, we have two different processes that now I need to start rethinking now that I’m learning more about lean. One is that we’ll get the slingshots back; they go to the machine shop. Now, one of the things we haven’t invested in is specialized equipment to just drill the slingshot holes. So, they go to the machine shop in a batch and the holes get drilled in the slingshot frame. They come back to us and then we put the heli-coils in, and then they go out to be wrapped. So, so far, we’re not doing single piece flow; we’re doing small batches. But that’s driven by the fact we have to do it out-of-house, and it’s just not economical to do that as single piece flow – yet (the painting and the cutting). So, then what we do is those slingshots go to two places. Part of them go to the mountains, because we have capabilities there, and we anticipate inventory, we build to inventory, so probably two-thirds of them go to the mountains, get wrapped there. A third of them stay here. And the reason why we keep those here is to accommodate for anywhere that someone has a custom paracord color we want (because we wrap the handles with paracord), and it’s easy to do a color change. Or, we missed on our projections. So now this is a little bit of a challenge because now I end up, when they come back from the mountains after they get wrapped, so maybe two-thirds of my slingshots have already been wrapped in specific. And so those colors, it may be a third woodland camo, a third desert camo, a third black. So, now what I’ve got is I have frames that have paracord on them with heli-coils in them, and they’re ready for final assembly. So, generally, what we do is at this point we switch over and go to single piece flow. So, what I want to do is kind of put a bookmark here in our conversation, so we’re going to come back to this point.

So this is happening; our website, you know, our main customer contact point. And so folks are visiting the website and placing orders. So if you visit the Montie Gear website and you place an order, that order gets recorded on our website. And then, usually three times a week – Monday evening, Wednesday evening and Saturday, I’ll go and I’ll download new orders. So, when I download the orders, so I download it into a piece of middle-ware called T-HUB. T-HUB brings up a visual dashboard that shows me what has been paid for, what hasn’t been paid for, what has been shipped, what hasn’t been shipped, and what has been transferred to QuickBooks. And so I take this and I use T-HUB to print out a sales receipt. So I take those sales receipts and then we have a table. And so each sales receipt sits on that table and becomes the routing sheet for the order. What I didn’t realize in doing all this was I was already taking somewhat of a step towards a combine by how we set this up. So those sheets sit on the table. When Lars comes in, he instantly has a visual indicator of what needs to be built. Now, he can also go back to T-HUB and look it up. A lot of times, though, he doesn’t need to because I have already printed them out so he can take a look at it, and instantly know what he needs to build. So, this is a great way we’re communicating; so everybody knows how many orders we have that are unfulfilled. Now, kind of a next step on that would be to track days until shipment. So this is kind of one of the things that we need to do, is to track how long it’s been since the shipment.

Now another thing we need to do is automate the receipt of orders coming from Amazon. Right now, we don’t (and from eBay); right now we process those manually; so that’s a step. Once we get all that going through T-HUB, then we’ll have that computer visualization of, you know, what’s shipped and what hasn’t and what’s been paid for. And then we’ll also the table with a slip and a space for every order. So, as the order gets fulfilled, it gets passed to the next step. So Lars does single piece flow on the assembly – for example, the slingshot. Some products we build to inventory. Does single piece flow on the slingshot, puts it in a box, sets it for on the next table, where, when I come in then I take that box and ship it. Now, the beauty of it here is that we’re using this dashboard and we’re using the presence of this sheet of paper to show us, you know, so in an instant I know how packages I generally have to ship, because its sitting right there. So it’s very quick. Now, then what happens, I take that . . . after its shipped, I take that sales receipt and it goes into the “shipped sales receipt” or “done” pile. And then that gets filed away. And then, of course, the process of shipping it also means that T-HUB records it as being shipped. So, in this way, that’s a nice streamlined way of doing that. What we need to do to be more lean is to track, for example, number of days until shipment; you know, what was the reason why we didn’t ship on a day. So if Lars comes in, I need to track failures; you know, what we were missing, and then track how long it took to rectify that, who’s responsible. So maybe we don’t have a part or are missing some screws. So if we track that and find out that, Wow, we had seventy-seven times we were out of screws, and that held us up from shipping, then we need to keep more screws on hand; or we need to have a better way of monitoring that. So, at some point, what we need to do is actually to track our inventory so that there’s a card, so we can visualize, you know, what’s our safety inventory, what’s our normal consumption, so that when someone goes into the supermarket – which is where we store our parts that are ready to either for final assembly or to ship – when they go in that supermarket, then there’s an easy way to see what we’re low on. So that’s another aspect of lean that’s very common, is that you monitor that visually.

So, at this point, one of the things I’m starting to go after is to say, Okay, how do we monitor our process in a way that I can maintain (or everybody can help maintain), that’s not painfully expensive to monitor, but also lets everybody know where we are, how we’re doing, and gives us information for continuous improvement. So, that’s kind of the next step is to think that through; you know, is it a board? How do we track these things? And so, I’m open to suggestions. Anybody that wants to come by, make some suggestions on how to track this. You know, between X-Cart and T-HUB and QuickBooks, you know, what can we use to have a continuous monitoring of our process so that we can improve that; use our resources more wisely; and, you know, maximize our through-put flow-wise.

So, I hope this gives you a little insight into where we are now and kind of thinking and the process. It’s definitely a big challenge. A lot of these things, you’ve got to change at a very root level of how you do business and how you spend your day. It’s not just a matter of adding on a piece of software. A lot of times it’s a matter of just physically changing how you conduct your business. And that’s one of the tough things about lean, is that it’s a culture change. It’s not just something you throw over the top that adds a burden. If you do that, if all you do is just bolt it onto the top, you never really get a lot of benefit. You’ll never follow it. With lean, you’ve got to dig in and make a real in-depth change.

So, I hope this was a good talk for everybody. I appreciate you listening. Please don’t hesitate to send me an email. Come by the shop and you can see where we are in our lean transformation. And have a great day. Bye-bye.

[Closing music]

END AUDIO