In this Issue:

- Sign up for Customer Requirements Lunch and Learn on June 4

- Last Chance to RSVP Last Stand on Troublesome Gap Event for Montie Design Clients and Friends

- New Class – Getting Your Product To Market 101 – Taught by Montie Roland

- Product Design Win – Slingshot Holster

- Spring Intern Update – Coco’s Bench and Rachael’s Utensil Holders

Sign Up for “Difficulty Getting Real Customer Requirements” Lunch & Learn on June 4th

Andy Roth will give us practical tools and advice on gathering customer requirements. Andy has almost 15 years of experience managing complex corporate projects while at Tekelec. Put his experience and knowledge to work for you at this insightful Lunch & Learn. This is a great way to sharpen your project management skills and network with other engineers and project managers. Click here to sign up.

The Montie Design Lunch and Learn series is developed to connect professionals involved in the technical or business side of designing and producing innovative products and technologies with one another as well as with speakers, who have agreed to share their knowledge, professionalism, and willingness to support entrepreneurial growth.

Upcoming events include:

June 4 – Difficulty Getting Real Customer Requirements?

June 18 – How to Size a Battery

June 28 – Final Friday End of Quarter Networking Event

July 18 – Flex Circuits 101

Aug 7 – Social Reviews 101

Aug 21 – Designing Rubber Keypads

Sept 11 – Personalities & Personas

Sept 25 – Rapid Prototyping, Rapid Machining and Rapid Sheetmetal

Sept 27 – Final Friday End of Quarter Networking Event

RSVP by Friday and Join Us at the Last Stand on Troublesome Gap

Every year Montie Design staff, industry peers, and clients meet up in the mountains out at beautiful Troublesome Gap, NC for a weekend of fun on Memorial Day Weekend. Sit by the campfire and relax, and be sure to join in the fun of our first annual Zombie shooting course and competition. In order to complete the course, you engage the Zombie targets with a rifle, pistol, shotgun and slingshot. The event is free, but an RSVP is required. RVSP to montie@montie.com. The brochure is available for download here.

Getting Your Product to Market 101 – How to Design, Prototype and Manufacture Your Product

A two day seminar that provides participants an overview of product development, prototyping, product manufacture, and low cost public relations tools to develop a “buzz” about the product. Hosted by Product Design Veteran and design firm owner Montie Roland

Class Description: Montie Design, an innovative concept-to-marketplace product design and development firm, has announced that Company President Montie Roland will host a two part class “How-to-Design-A-Product” in Morrisville on Tuesday, June 11, and Thursday, June 13.

Roland, a product design veteran, will be generating a casual dialog where attendees can learn about how to develop a product or service from concept through the patent process all the way through to the point of manufacturing and selling the product.

With a small manufacturing facility in Spring Creek complimenting its main operation in the Triangle region of North Carolina, Montie Design has a successful history of taking products from concept to marketplace. The firm’s team of product design professionals has over 140 years of knowledge and experience helping clients realize products that are economical to manufacture, elegant and robust. Paying special attention to achieving excellence in functionality, operability, value and aesthetics regardless of market or industry, Montie Design staffers have helped turn over 750 exciting product ideas into reality.

In addition to serving customers in a myriad of industry sectors, Montie Design produces its own Montie Gear line of outdoor equipment, including a slingshot; ultralight knife; multi-purpose tree hook archery rest for sturdy support of a bow, crossbow, or rifle with a sling; a camp rack designed to hold pots, lids, serving bowls and utensils off the ground to dry after cleaning; and the popular X-Rest and AR-Rest shooting supports for hunters and recreational shooters.

All equipment in the Montie Gear line is heirloom quality, Troublesome Gap tough. Located near the peak of Hap Mountain overlooking Spring Creek, North Carolina, Troublesome Gap is a rugged mountain area where Montie Gear prototypes are tested and evaluated.

Sign up at http://www.eventbrite.com/event/6546126641/eorg

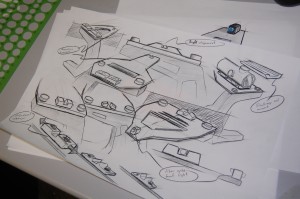

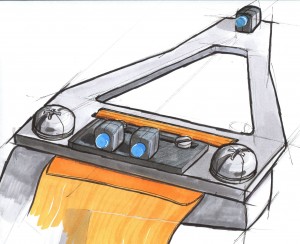

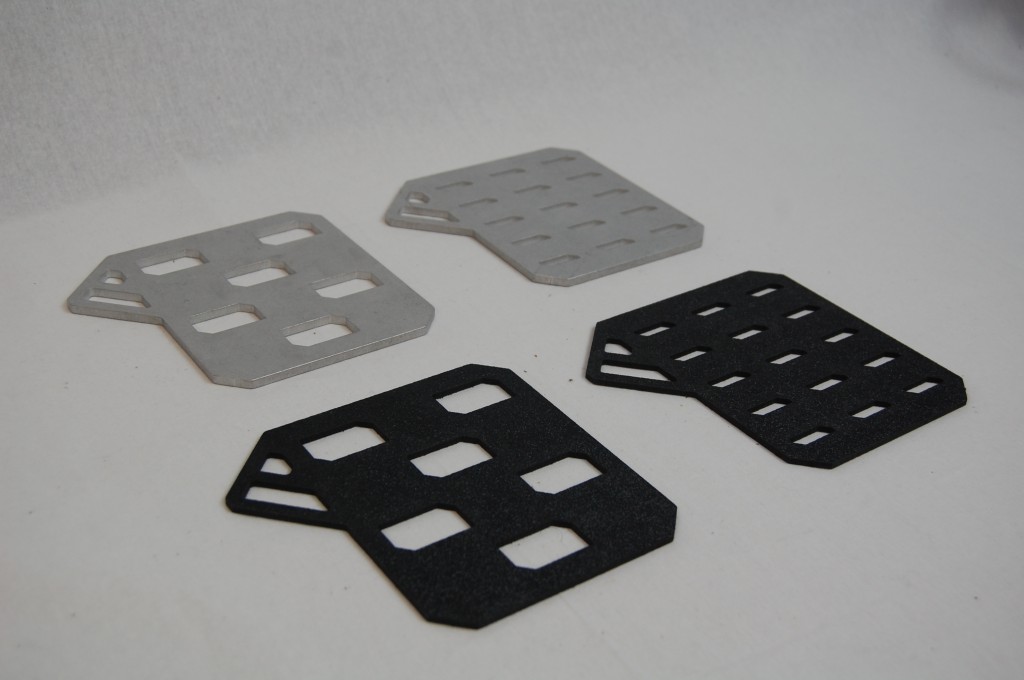

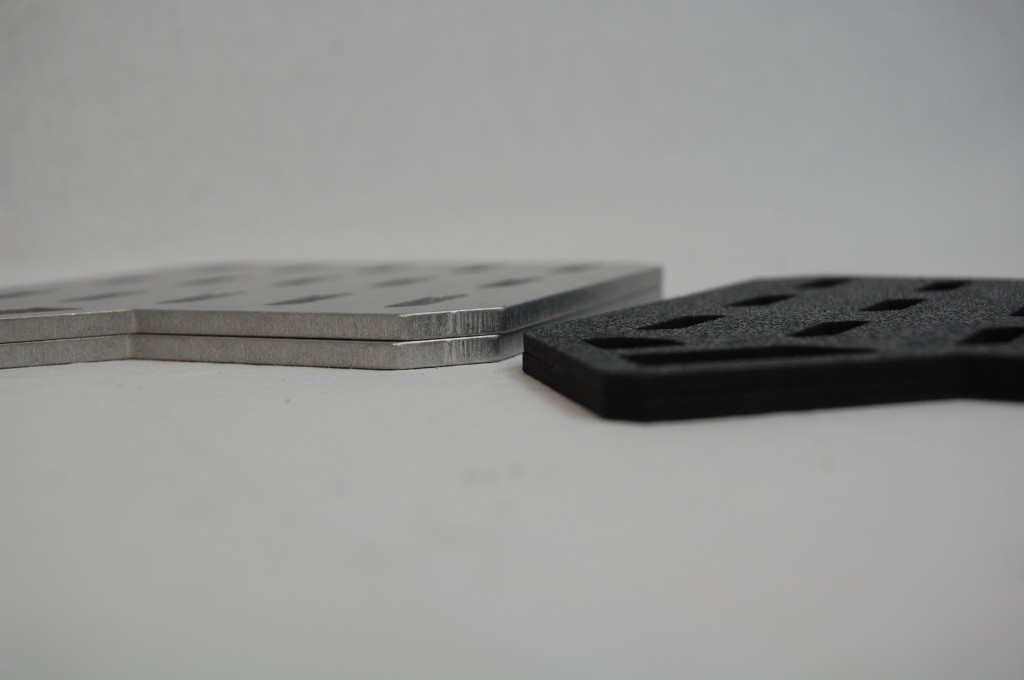

Design Win – Slingshot Holster

The mighty Montie Gear Y-Shot slingshot now is even better with a rugged and locally made holster. We call it a win because the initial production run is almost sold out before the die cutting tools are even complete. Call or email us today to find out how we can make your product a winner too! Click here to see the holster on the www.montiegear.com website.

Intern Spotlights: Kitchen Utensil Holders, Campfire Bench

Spring 2013 Montie Design interns Rachael Hughes and Coco Feng have been working on some very interesting concepts for additions to the Montie Gear line of outdoor camping equipment. Rachael is closing in on a final design for something to keep utensils from setting on surfaces typical to camping, such as picnic tables or coolers — where they may attract wildlife and collect bugs or harmful bacteria – while Coco is working on an outdoor wooden bench design which solves a customer need for hanging backpacks, coats and garbage bags.

We are proud to say that the wood for the bench was sawn on site at our Spring Creek facility from locally harvested timber. Otherwise the sizes of lumber we used wouldn’t have been commercially available. The seat is made from a single pine board over 16″ wide by 1-3/4″ thick. The final shapes were cut from 20″ wide boards using a water jet giving a very precise fit.

Designs can be viewed online at blog.montiegear.com. Montie Design has a long history of hosting interns from colleges throughout North Carolina and from Sweden in order to prepare them for their chosen fields and help them build a portfolio of solid work for prospective employers.

Finally A Way to Hang Your Hand or Bath Towels to Dry

Towels and Sponges Kept Off the Ground to Dry

Finally A Way to Dry Your Silverware and Untensils after Washing

Silverware and Untensils Hanging to Dry

Sit by the Campfire in Style!

Prototype Bench – yes, the seat is a single board 16″ wide by 1-3/4″ thick!

Prototype Bench – come by and give it a test sit

We Can Help! Call Today

Want to talk product development or need help with a project? Don’t hesitate to contact Montie Roland at 919-481-1845×103 or montie@montie.com.-7987

About Montie Design

Montie Design is an innovation and commercialization firm with core competencies in mechanical engineering and industrial design. Active in the product design, defense, and technology sectors, we leverage years of industry leadership and extensive technical capabilities to help clients take products from concept to marketplace that are economical to manufacture, elegant and robust. Montie Design is a North Carolina company headquartered in the Research Triangle region with clients across the country and overseas. We are dedicated to economic development throughout our home state and furthering excellence in design and engineering. For more information, visit

www.montie.com or download the capabilities statement in PDF format

here.